Series D11 knife gate valve is widely used in many different kinds of media such as pulp, sludge, biomass, powder and wastes. The valve has a gate with a bevel edge that effectively cuts through different media. In closed position the gate is pushed onto the seat for a tight and reliable sealing. Series D11 knife gate valve is widely used in many different kinds of media such as pulp, sludge, biomass, powder and wastes. The valve has a gate with a bevel edge that effectively cuts through different media. In closed position the gate is pushed onto the seat for a tight and reliable sealing.

FEATURES • Reliable shut-off

• Solid and flexible top works

• Many materials available for different grade of corrosion

• Wafer Semi-lug mounting

• Unidirectional tightness, direction indication thanks to the arrow on the body

• The gate is guided in the body and has little clearance

• Packing and O-ring to assure the elasticity and decrease the operating torque

| Design standard | MSS SP-81 | | Connection | Wafer Semi-lug | | Size | 2"-48" | | Pressure rating | 2"-5" 200PSI, 6"-12" 150PSI, 14"-24" 100PSI, 28"-48" 60PSI | | Face to face | MSS SP-81, TAPPI TIS 405-8 | | Temperature range | -29°C to +600°C | | Corrosion protection | Fusioin bonded epoxy for ductile iron body, Passivation for SS |

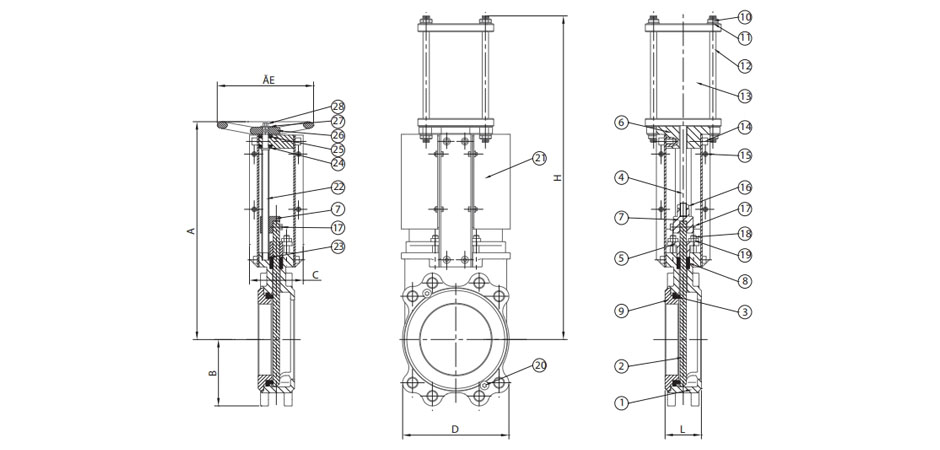

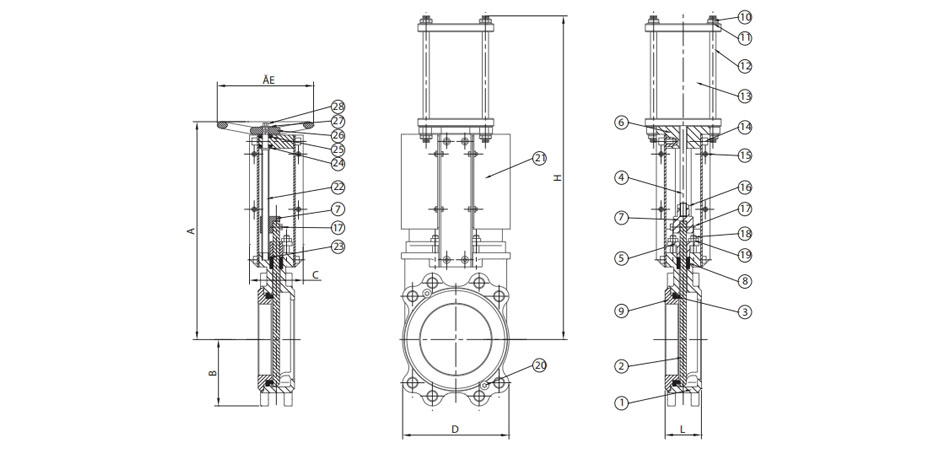

| No. | Part name | Material | | 1 | Body | CF8M | CF8 | ASTM A536 65-45-12 | | 2 | Gate | SS316L | SS304 | SS304 | | 3 | Seat | EPDM,NBR,FPM,PTFE with FPM O ring | | 4 | Piston rod | SS304 | SS304 | SS430 | | 5 | Gland | CF8M | CF8 | ASTM A536 65-45-12 | | 6 | Yoke | CF8M | CF8 | ASTM A536 65-45-12 | | 7 | Gate clevis | SS304 | SS304 | ASTM A536 65-45-12 | | 8 | Packing | PTFE | | 9 | Seat retainer | SS316 | SS304 | Steel | | 10 | Nut | SS304 | SS304 | SS304 | | 11 | Washer | SS304 | SS304 | SS304 | | 12 | Tie rod | SS304 | SS304 | SS304 | | 13 | Cylinder | Aluminium alloy | | 14 | Bolt | SS304 | SS304 | SS304 | | 15 | Screw | SS304 | SS304 | SS304 | | 16 | Locking nut | SS304 | SS304 | SS304 | | 17 | Screw | SS304 | SS304 | SS304 | | 18 | Stud | SS304 | SS304 | SS304 | | 19 | Nut | SS304 | SS304 | SS304 | | 20 | Screw | SS304 | SS304 | SS304 | | 21 | Gate guard | SS304 | SS304 | Steel coated | | 22 | Stem | SS304 | SS304 | SS410 | | 23 | Bearing | Bronze with oil | | 24 | Bearing | Brass | | 25 | Slide washer | POM | | 26 | Handwheel | CF8 | CF8 | ASTM A536 65-45-12 | | 27 | Washer | SS304 | SS304 | SS304 | | 28 | Screw | SS304 | SS304 | SS304 |

| SIZE | A | B | C | D | E | H | L | Handwheel valve WT(kg) | | DN | INCH | | 50 | 2" | 360 | 56 | 90 | 120 | 200 | 470 | 41 | 6 | | 65 | 2 1/2" | 380 | 65 | 90 | 130 | 200 | 490 | 41 | 7 | | 80 | 3" | 405 | 90 | 90 | 135 | 200 | 515 | 51 | 8 | | 100 | 4" | 455 | 105 | 90 | 155 | 200 | 565 | 51 | 10 | | 125 | 5" | 495 | 116 | 105 | 180 | 260 | 655 | 56 | 13 | | 150 | 6" | 550 | 130 | 105 | 205 | 260 | 710 | 60 | 15 | | 200 | 8" | 695 | 160 | 105 | 270 | 260 | 925 | 60 | 30 | | 250 | 10" | 780 | 195 | 150 | 320 | 330 | 1115 | 69 | 40 | | 300 | 12" | 880 | 230 | 150 | 380 | 330 | 1215 | 78 | 55 | | 350 | 14" | 995 | 210 | 150 | 420 | 330 | 1510 | 78 | 90 | | 400 | 16" | 1085 | 245 | 180 | 490 | 420 | 1600 | 89 | 120 | | 450 | 18" | 1180 | 280 | 180 | 560 | 420 | 1680 | 89 | 180 | | 500 | 20" | 1335 | 315 | 260 | 630 | 550 | 1940 | 114 | 240 | | 600 | 24" | 1560 | 370 | 260 | 740 | 550 | 2250 | 114 | 340 | | 700 | 28" | 1750 | 400 | 320 | 865 | 650 | 2610 | 118 | 460 | | 750 | 30" | 1880 | 430 | 320 | 930 | 650 | 2680 | 118 | 550 | | 800 | 32" | 1970 | 450 | 320 | 985 | 650 | 2830 | 118 | 700 | | 900 | 36" | 2220 | 580 | 320 | 1160 | 650 | 3140 | 118 | 900 | | 1000 | 40" | 2400 | 640 | 400 | 1280 | 800 | 3480 | 150 | 1500 | | 1200 | 48" | 2900 | 750 | 500 | 1500 | 800 | 4400 | 150 | 2200 |

| Design standard | MSS SP-81 | | Connection | Wafer Semi-lug | | Size | 2"-48" | | Pressure rating | 2"-5" 200PSI, 6"-12" 150PSI, 14"-24" 100PSI, 28"-48" 60PSI | | Face to face | MSS SP-81, TAPPI TIS 405-8 | | Temperature range | -29°C to +600°C | | Corrosion protection | Fusioin bonded epoxy for ductile iron body, Passivation for SS |

Series D11 knife gate valve is widely used in many different kinds of media such as pulp, sludge, biomass, powder and wastes. The valve has a gate with a bevel edge that effectively cuts through different media. In closed position the gate is pushed onto the seat for a tight and reliable sealing. Series D11 knife gate valve is widely used in many different kinds of media such as pulp, sludge, biomass, powder and wastes. The valve has a gate with a bevel edge that effectively cuts through different media. In closed position the gate is pushed onto the seat for a tight and reliable sealing.

FEATURES • Reliable shut-off

• Solid and flexible top works

• Many materials available for different grade of corrosion

• Wafer Semi-lug mounting

• Unidirectional tightness, direction indication thanks to the arrow on the body

• The gate is guided in the body and has little clearance

• Packing and O-ring to assure the elasticity and decrease the operating torque

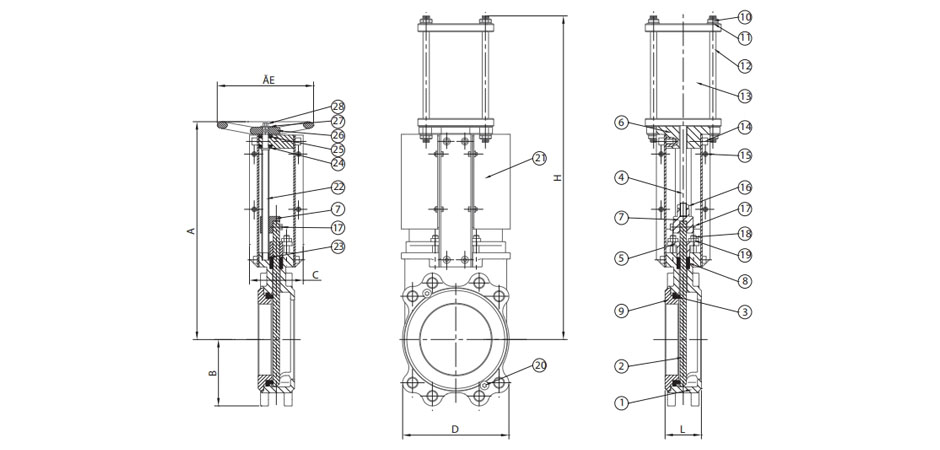

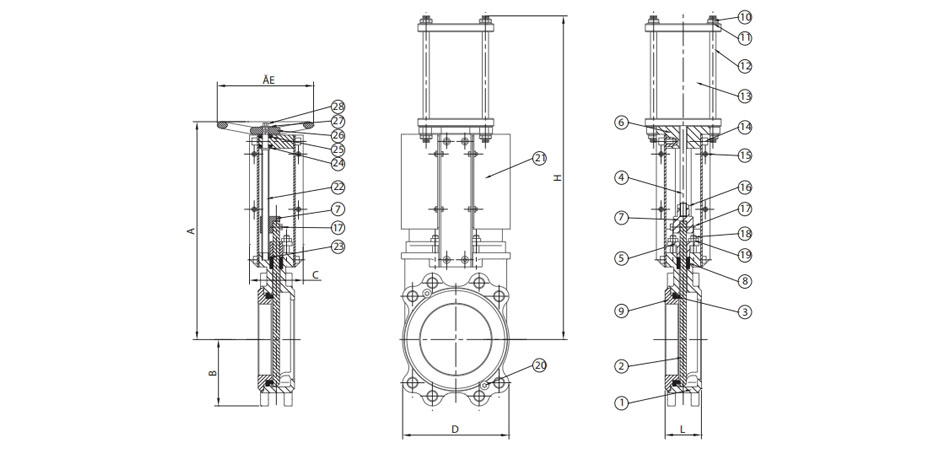

| No. | Part name | Material | | 1 | Body | CF8M | CF8 | ASTM A536 65-45-12 | | 2 | Gate | SS316L | SS304 | SS304 | | 3 | Seat | EPDM,NBR,FPM,PTFE with FPM O ring | | 4 | Piston rod | SS304 | SS304 | SS430 | | 5 | Gland | CF8M | CF8 | ASTM A536 65-45-12 | | 6 | Yoke | CF8M | CF8 | ASTM A536 65-45-12 | | 7 | Gate clevis | SS304 | SS304 | ASTM A536 65-45-12 | | 8 | Packing | PTFE | | 9 | Seat retainer | SS316 | SS304 | Steel | | 10 | Nut | SS304 | SS304 | SS304 | | 11 | Washer | SS304 | SS304 | SS304 | | 12 | Tie rod | SS304 | SS304 | SS304 | | 13 | Cylinder | Aluminium alloy | | 14 | Bolt | SS304 | SS304 | SS304 | | 15 | Screw | SS304 | SS304 | SS304 | | 16 | Locking nut | SS304 | SS304 | SS304 | | 17 | Screw | SS304 | SS304 | SS304 | | 18 | Stud | SS304 | SS304 | SS304 | | 19 | Nut | SS304 | SS304 | SS304 | | 20 | Screw | SS304 | SS304 | SS304 | | 21 | Gate guard | SS304 | SS304 | Steel coated | | 22 | Stem | SS304 | SS304 | SS410 | | 23 | Bearing | Bronze with oil | | 24 | Bearing | Brass | | 25 | Slide washer | POM | | 26 | Handwheel | CF8 | CF8 | ASTM A536 65-45-12 | | 27 | Washer | SS304 | SS304 | SS304 | | 28 | Screw | SS304 | SS304 | SS304 |

| SIZE | A | B | C | D | E | H | L | Handwheel valve WT(kg) | | DN | INCH | | 50 | 2" | 360 | 56 | 90 | 120 | 200 | 470 | 41 | 6 | | 65 | 2 1/2" | 380 | 65 | 90 | 130 | 200 | 490 | 41 | 7 | | 80 | 3" | 405 | 90 | 90 | 135 | 200 | 515 | 51 | 8 | | 100 | 4" | 455 | 105 | 90 | 155 | 200 | 565 | 51 | 10 | | 125 | 5" | 495 | 116 | 105 | 180 | 260 | 655 | 56 | 13 | | 150 | 6" | 550 | 130 | 105 | 205 | 260 | 710 | 60 | 15 | | 200 | 8" | 695 | 160 | 105 | 270 | 260 | 925 | 60 | 30 | | 250 | 10" | 780 | 195 | 150 | 320 | 330 | 1115 | 69 | 40 | | 300 | 12" | 880 | 230 | 150 | 380 | 330 | 1215 | 78 | 55 | | 350 | 14" | 995 | 210 | 150 | 420 | 330 | 1510 | 78 | 90 | | 400 | 16" | 1085 | 245 | 180 | 490 | 420 | 1600 | 89 | 120 | | 450 | 18" | 1180 | 280 | 180 | 560 | 420 | 1680 | 89 | 180 | | 500 | 20" | 1335 | 315 | 260 | 630 | 550 | 1940 | 114 | 240 | | 600 | 24" | 1560 | 370 | 260 | 740 | 550 | 2250 | 114 | 340 | | 700 | 28" | 1750 | 400 | 320 | 865 | 650 | 2610 | 118 | 460 | | 750 | 30" | 1880 | 430 | 320 | 930 | 650 | 2680 | 118 | 550 | | 800 | 32" | 1970 | 450 | 320 | 985 | 650 | 2830 | 118 | 700 | | 900 | 36" | 2220 | 580 | 320 | 1160 | 650 | 3140 | 118 | 900 | | 1000 | 40" | 2400 | 640 | 400 | 1280 | 800 | 3480 | 150 | 1500 | | 1200 | 48" | 2900 | 750 | 500 | 1500 | 800 | 4400 | 150 | 2200 |

|

Knife Gate Valves ★★★

Knife Gate Valves ★★★