Series C12 wafer dual check valve is a self-operating check valve that is desirable to permit flow in one direction and prevent backflow in the opposite direction. The plate opens in case that the upstream pressure exceeds the downstream pressure and the spring elasticity. When the flow velocity upstream decreases or ceases, the spring will automatically close the dual plates prior to flow reversal. This creates a positive shutoff against flow reversal and eliminates system surges and water hammer. Series C12 wafer dual check valve is a self-operating check valve that is desirable to permit flow in one direction and prevent backflow in the opposite direction. The plate opens in case that the upstream pressure exceeds the downstream pressure and the spring elasticity. When the flow velocity upstream decreases or ceases, the spring will automatically close the dual plates prior to flow reversal. This creates a positive shutoff against flow reversal and eliminates system surges and water hammer.

FEATURES • Short face-to-face dimension• Lighter weight than conventional full-body check valves

• Low cracking pressure because of double disc design?The stop shaft stabilizes the plates under high flow rates• Long leaf springs prevent rubbing of plates on seat

| Connection | Wafer | | Nominal diameter | DN50-DN1200 | | Pressure rating | PN10, PN16, PN25, ANSI CLASS150 | | Face to face | EN558 Series 16 | | Temperature range | -20°C to +85°C for NBR seat | | -20°C to +130°C for EPDM seat | | -20°C to +180°C for FPM seat | | Coating | Fusion bonded epoxy |

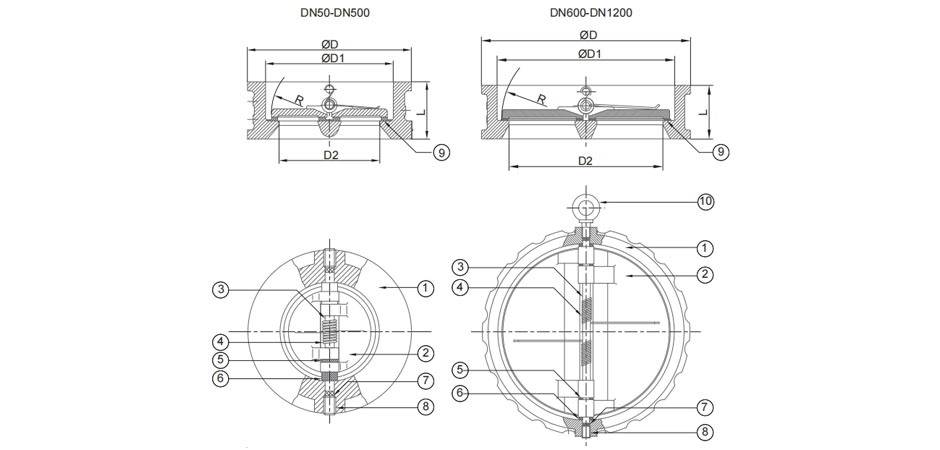

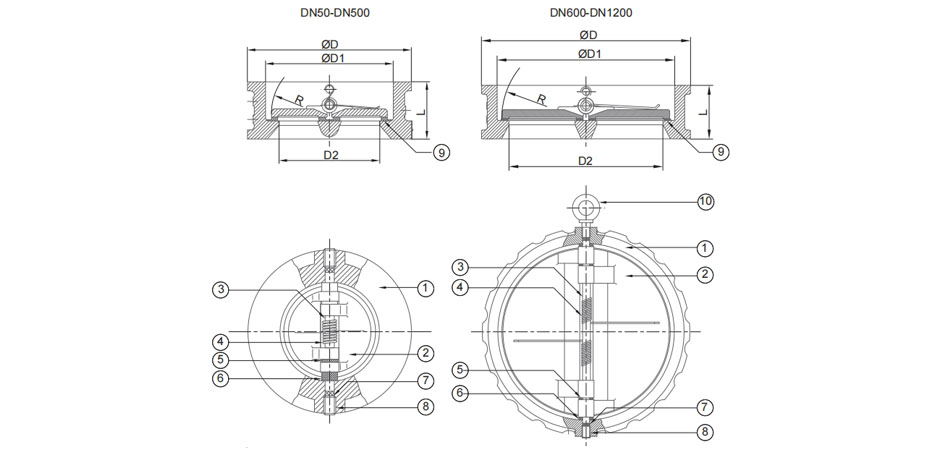

| No. | Part name | Material | | 1 | Body | Ductile Iron | | 2 | Disc | CF8, CF8M | | 3 | Stem | SS304, SS316 | | 4 | Spring | SS304, SS316 | | 5 | Bearing | PTFE | | 6 | Bearing | PTFE | | 7 | O-Ring | Same as seat | | 8 | Hex Screw | SS304, SS316 | | 9 | Seat | NBR, EPDM, FPM | | 10 | Eye Bolt | SS304, SS316 |

| SIZE | D | D1 | D2 | L | R | WT(kg) | | DN | INCH | PN10 | PN16 | PN25 | Class150 | | 50 | 2" | 109 | 109 | 109 | 104 | 65 | 40 | 43 | 29 | 1.5 | | 65 | 2 1/2" | 129 | 129 | 129 | 123 | 80 | 60 | 46 | 36 | 2.4 | | 80 | 3" | 144 | 144 | 144 | 136 | 94 | 70 | 64 | 43 | 3.6 | | 100 | 4" | 164 | 164 | 164 | 174 | 117 | 88 | 64 | 53 | 5.7 | | 125 | 5" | 194 | 194 | 196 | 196 | 145 | 115 | 70 | 66 | 7.3 | | 150 | 6" | 220 | 220 | 226 | 222 | 170 | 134 | 76 | 79 | 9 | | 200 | 8" | 275 | 275 | 286 | 279 | 224 | 182 | 89 | 104 | 17.2 | | 250 | 10" | 330 | 330 | 343 | 339 | 265 | 220 | 114 | 127 | 26.3 | | 300 | 12" | 380 | 386 | 403 | 409 | 310 | 260 | 114 | 148 | 42.1 | | 350 | 14" | 440 | 446 | 460 | 450 | 360 | 298 | 127 | 172 | 55.2 | | 400 | 16" | 491 | 494 | 517 | 514 | 410 | 350 | 140 | 197 | 75.3 | | 450 | 18" | 541 | 558 | 567 | 549 | 450 | 385 | 152 | 218 | 101.2 | | 500 | 20" | 596 | 620 | 627 | 606 | 505 | 438 | 152 | 241 | 111.3 | | 600 | 24" | 698 | 737 | 734 | 717 | 624 | 538 | 178 | 295 | 172 | | 700 | 28" | 813 | 807 | 836 | 831 | 720 | 680 | 229 | 350 | 340 | | 800 | 32" | 920 | 914 | 945 | 939 | 825 | 770 | 241 | 400 | 520 | | 900 | 36" | 1020 | 1014 | 1045 | 1047 | 903 | 898 | 241 | 450 | 600 | | 1000 | 40" | 1127 | 1131 | 1158 | 1162 | 1055 | 1050 | 300 | 500 | 820 | | 1200 | 48" | 1344 | 1344 | | 1384 | 1205 | 1200 | 350 | 600 | 1300 |

| Connection | Wafer | | Nominal diameter | DN50-DN1200 | | Pressure rating | PN10, PN16, PN25, ANSI CLASS150 | | Face to face | EN558 Series 16 | | Temperature range | -20°C to +85°C for NBR seat | | -20°C to +130°C for EPDM seat | | -20°C to +180°C for FPM seat | | Coating | Fusion bonded epoxy |

Series C12 wafer dual check valve is a self-operating check valve that is desirable to permit flow in one direction and prevent backflow in the opposite direction. The plate opens in case that the upstream pressure exceeds the downstream pressure and the spring elasticity. When the flow velocity upstream decreases or ceases, the spring will automatically close the dual plates prior to flow reversal. This creates a positive shutoff against flow reversal and eliminates system surges and water hammer. Series C12 wafer dual check valve is a self-operating check valve that is desirable to permit flow in one direction and prevent backflow in the opposite direction. The plate opens in case that the upstream pressure exceeds the downstream pressure and the spring elasticity. When the flow velocity upstream decreases or ceases, the spring will automatically close the dual plates prior to flow reversal. This creates a positive shutoff against flow reversal and eliminates system surges and water hammer.

FEATURES • Short face-to-face dimension• Lighter weight than conventional full-body check valves

• Low cracking pressure because of double disc design?The stop shaft stabilizes the plates under high flow rates• Long leaf springs prevent rubbing of plates on seat

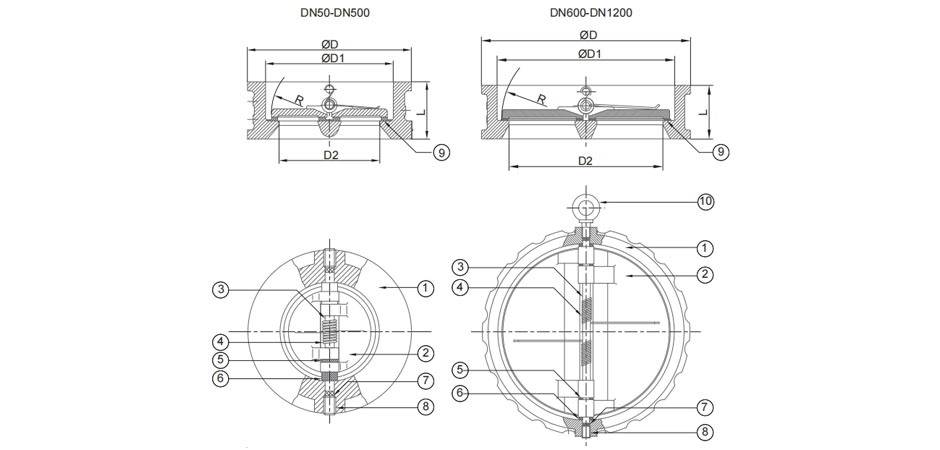

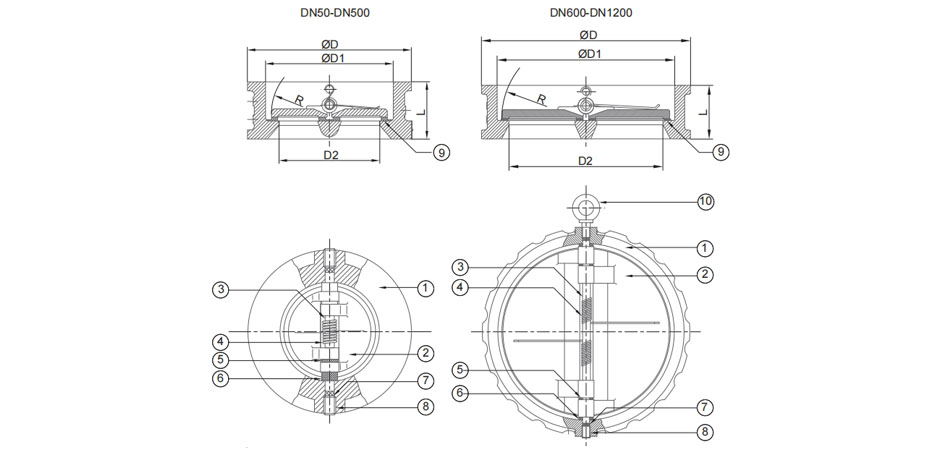

| No. | Part name | Material | | 1 | Body | Ductile Iron | | 2 | Disc | CF8, CF8M | | 3 | Stem | SS304, SS316 | | 4 | Spring | SS304, SS316 | | 5 | Bearing | PTFE | | 6 | Bearing | PTFE | | 7 | O-Ring | Same as seat | | 8 | Hex Screw | SS304, SS316 | | 9 | Seat | NBR, EPDM, FPM | | 10 | Eye Bolt | SS304, SS316 |

| SIZE | D | D1 | D2 | L | R | WT(kg) | | DN | INCH | PN10 | PN16 | PN25 | Class150 | | 50 | 2" | 109 | 109 | 109 | 104 | 65 | 40 | 43 | 29 | 1.5 | | 65 | 2 1/2" | 129 | 129 | 129 | 123 | 80 | 60 | 46 | 36 | 2.4 | | 80 | 3" | 144 | 144 | 144 | 136 | 94 | 70 | 64 | 43 | 3.6 | | 100 | 4" | 164 | 164 | 164 | 174 | 117 | 88 | 64 | 53 | 5.7 | | 125 | 5" | 194 | 194 | 196 | 196 | 145 | 115 | 70 | 66 | 7.3 | | 150 | 6" | 220 | 220 | 226 | 222 | 170 | 134 | 76 | 79 | 9 | | 200 | 8" | 275 | 275 | 286 | 279 | 224 | 182 | 89 | 104 | 17.2 | | 250 | 10" | 330 | 330 | 343 | 339 | 265 | 220 | 114 | 127 | 26.3 | | 300 | 12" | 380 | 386 | 403 | 409 | 310 | 260 | 114 | 148 | 42.1 | | 350 | 14" | 440 | 446 | 460 | 450 | 360 | 298 | 127 | 172 | 55.2 | | 400 | 16" | 491 | 494 | 517 | 514 | 410 | 350 | 140 | 197 | 75.3 | | 450 | 18" | 541 | 558 | 567 | 549 | 450 | 385 | 152 | 218 | 101.2 | | 500 | 20" | 596 | 620 | 627 | 606 | 505 | 438 | 152 | 241 | 111.3 | | 600 | 24" | 698 | 737 | 734 | 717 | 624 | 538 | 178 | 295 | 172 | | 700 | 28" | 813 | 807 | 836 | 831 | 720 | 680 | 229 | 350 | 340 | | 800 | 32" | 920 | 914 | 945 | 939 | 825 | 770 | 241 | 400 | 520 | | 900 | 36" | 1020 | 1014 | 1045 | 1047 | 903 | 898 | 241 | 450 | 600 | | 1000 | 40" | 1127 | 1131 | 1158 | 1162 | 1055 | 1050 | 300 | 500 | 820 | | 1200 | 48" | 1344 | 1344 | | 1384 | 1205 | 1200 | 350 | 600 | 1300 |

|

Wafer Dual Check Valves ★★★★

Wafer Dual Check Valves ★★★★