The unique feature of the dome valve is that it cuts off the material flowing or stationary column of material to the pressure tank and then closes sealing. This ensures 100% filling of the pressure tank.

B72INF Dome type valve is a high performance special valve and is used all over the world in Material Handling Systems in a wide range of industries. Dome type valves are capable of handling powdery and granular materials like lithium battery materials, fly. ash, bottom ash, boiler bed sand and limestone. B72lNF Dome type valve has a simple construction and automatically inflating sealing mechanism which operates with compressed air ensuring minimized wearing. The valve closes also through the material opening the material flow only a quarter turn from fully closed to fully open. The design of inflatable seat Dome type valve makes it extremely reliable and easy to maintain, providing long maintenance intervals.

Since there is no friction between the ball and the seat when valve is operated, a B72lNF Dome type valve can reach a life of more than three million cycles, providing contact wear compensation even when the valve seat or balls severely abraded by material.

The advantageous performance features of Longer valve lite, Minimal seat wear, Ultra-low torque requirements, Lower actuator costs, full opening for material flow, Excellent for abrasive and dry solids, Low maintenance, All these points make the B72lNF a valve which will save a lot of cost for users and bring great benefits to customers for slurries, bulk powders, granules, irregular solids, gases and gaseous powders.

| Connection | Flange | | Nominal diameter | DN150-DN300 | | Max. working pressure | 10Bar | | Standard working pressure | Full vacuum to 8bar (According to air supply) | | Flange standard | EN1092 PN10/16,GB/T 9119 | | Structure length | EN558 Series 36 | | Top flange | ISO 5211 | | Seal test | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40° C to +350° C (Depending on pressure, medium and material) | | Operation | Pneumatic actuator(DA, SA) | | Torque | the torque varies according to different use of medium |

| Item | Parts | Material | Standard | Corrosion-resistant and wear-resistant

treatment or temperature Remarks | | 1 | Valve body | SS304 | ASTM A351 CF8 | Pickling Passivation | | SS304+ Tungsten carbide | ASTM A351 CF8+WC | Internal Tungsten carbide coating,

external pickling passivation | | SS304+Ceramic | ASTM A351 CF8+TC | Internal Ceramic coating,

external pickling passivation | | 2 | Valve disc | SS304 | ASTM A351 CF8 | Pickling Passivation | | SS304+ Tungsten carbide | ASTM A351 CF8+WC | Tungsten carbide coating | | SS304+Ceramic | ASTM A351 CF8+TC | Ceramic coating | | SS304 +weld Stellite | ASTM A351 CF8+STL | Sealing surface is built-up welding Stellite | | 3 | Valve seat | Wear-resistant EPDM | EPDM-HT | -20℃ ~120℃ | | H160 | H160 | -20℃ ~160℃ | | F260 | F260 | -20℃ ~260℃ | | Diamond carbon coating SS304 | ASTM A351 CF8+Diamond | -35℃ ~400℃ | | 4 | Stem | 431 | SS431 | | | 304 | SS304 | | | 5 | Packing gland | 304 | ASTM A351 CF8 | Pickling passivation | | 6 | Bottom cover | 316 | ASTM A351 CF8M | Pickling passivation | | 7 | Packing | RPTFE | RPTFE with 25% carbon

fiber reinforced | | | Graphite | Graphite | | | 8 | Bearing | RPTFE | RPTFE with Graphite I.D. | | SS316+high

temperature polymer | SS316 | High temperature polymer coating | | 9 | Screws | Stainless steel | SS304 | |

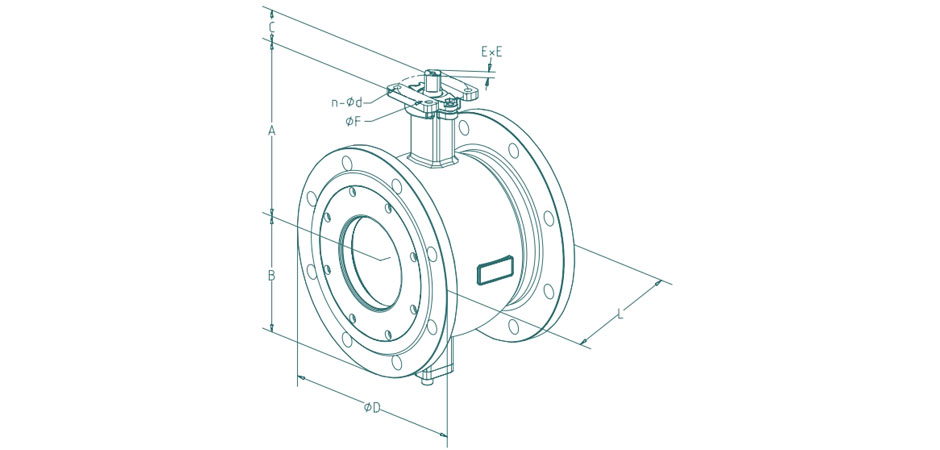

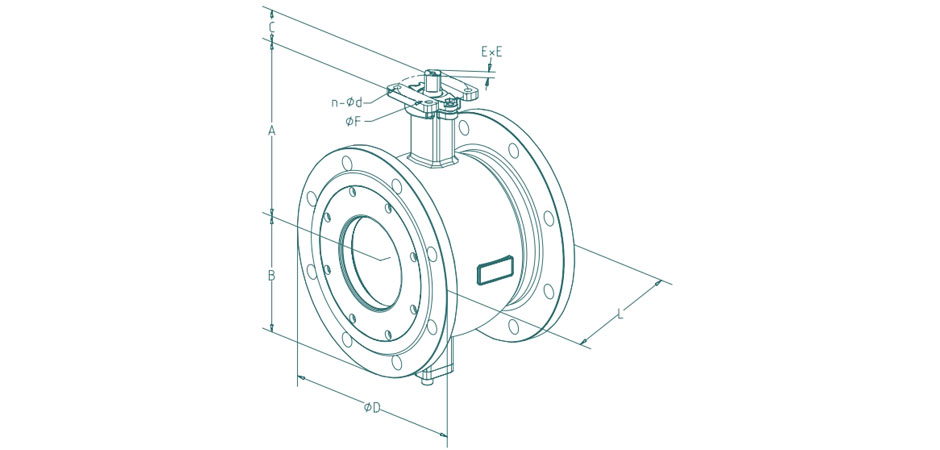

| Size | A | B | C | D | E | F | n | d | L | Weight

(kg) | | DN | INCH | | 150 | 6" | 203 | 150 | 18.5 | 285 | 17 | 102 | 4 | 11 | 229 | 50 | | 200 | 8" | 239 | 186 | 24.5 | 340 | 22 | 102 | 4 | 11 | 243 | 83 | | 250 | 10" | 275 | 226 | 24.5 | 395 | 22 | 102 | 4 | 11 | 297 | 120 | | 300 | 12" | 307 | 251 | 30 | 445 | 27 | 125 | 4 | 11 | 338 | 180 |

| Connection | Flange | | Nominal diameter | DN150-DN300 | | Max. working pressure | 10Bar | | Standard working pressure | Full vacuum to 8bar (According to air supply) | | Flange standard | EN1092 PN10/16,GB/T 9119 | | Structure length | EN558 Series 36 | | Top flange | ISO 5211 | | Seal test | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40° C to +350° C (Depending on pressure, medium and material) | | Operation | Pneumatic actuator(DA, SA) | | Torque | the torque varies according to different use of medium | The unique feature of the dome valve is that it cuts off the material flowing or stationary column of material to the pressure tank and then closes sealing. This ensures 100% filling of the pressure tank.

B72INF Dome type valve is a high performance special valve and is used all over the world in Material Handling Systems in a wide range of industries. Dome type valves are capable of handling powdery and granular materials like lithium battery materials, fly. ash, bottom ash, boiler bed sand and limestone. B72lNF Dome type valve has a simple construction and automatically inflating sealing mechanism which operates with compressed air ensuring minimized wearing. The valve closes also through the material opening the material flow only a quarter turn from fully closed to fully open. The design of inflatable seat Dome type valve makes it extremely reliable and easy to maintain, providing long maintenance intervals.

Since there is no friction between the ball and the seat when valve is operated, a B72lNF Dome type valve can reach a life of more than three million cycles, providing contact wear compensation even when the valve seat or balls severely abraded by material.

The advantageous performance features of Longer valve lite, Minimal seat wear, Ultra-low torque requirements, Lower actuator costs, full opening for material flow, Excellent for abrasive and dry solids, Low maintenance, All these points make the B72lNF a valve which will save a lot of cost for users and bring great benefits to customers for slurries, bulk powders, granules, irregular solids, gases and gaseous powders.

| Item | Parts | Material | Standard | Corrosion-resistant and wear-resistant

treatment or temperature Remarks | | 1 | Valve body | SS304 | ASTM A351 CF8 | Pickling Passivation | | SS304+ Tungsten carbide | ASTM A351 CF8+WC | Internal Tungsten carbide coating,

external pickling passivation | | SS304+Ceramic | ASTM A351 CF8+TC | Internal Ceramic coating,

external pickling passivation | | 2 | Valve disc | SS304 | ASTM A351 CF8 | Pickling Passivation | | SS304+ Tungsten carbide | ASTM A351 CF8+WC | Tungsten carbide coating | | SS304+Ceramic | ASTM A351 CF8+TC | Ceramic coating | | SS304 +weld Stellite | ASTM A351 CF8+STL | Sealing surface is built-up welding Stellite | | 3 | Valve seat | Wear-resistant EPDM | EPDM-HT | -20℃ ~120℃ | | H160 | H160 | -20℃ ~160℃ | | F260 | F260 | -20℃ ~260℃ | | Diamond carbon coating SS304 | ASTM A351 CF8+Diamond | -35℃ ~400℃ | | 4 | Stem | 431 | SS431 | | | 304 | SS304 | | | 5 | Packing gland | 304 | ASTM A351 CF8 | Pickling passivation | | 6 | Bottom cover | 316 | ASTM A351 CF8M | Pickling passivation | | 7 | Packing | RPTFE | RPTFE with 25% carbon

fiber reinforced | | | Graphite | Graphite | | | 8 | Bearing | RPTFE | RPTFE with Graphite I.D. | | SS316+high

temperature polymer | SS316 | High temperature polymer coating | | 9 | Screws | Stainless steel | SS304 | |

| Size | A | B | C | D | E | F | n | d | L | Weight

(kg) | | DN | INCH | | 150 | 6" | 203 | 150 | 18.5 | 285 | 17 | 102 | 4 | 11 | 229 | 50 | | 200 | 8" | 239 | 186 | 24.5 | 340 | 22 | 102 | 4 | 11 | 243 | 83 | | 250 | 10" | 275 | 226 | 24.5 | 395 | 22 | 102 | 4 | 11 | 297 | 120 | | 300 | 12" | 307 | 251 | 30 | 445 | 27 | 125 | 4 | 11 | 338 | 180 |

|

Dome Type Valve Plus ★★★★★

Dome Type Valve Plus ★★★★★