Series B53 forged body flanged ball valve is full bore designed according to API 608 and suitable for shutoff of various medium without much dirt such as air, gas, water, oil and liquids. FEATURES • Bolted bonnet and split body design Full bore for better Kv/Cv

• Blow-out-proof stem

• Both pure PTFE and 25% carbon fiber reinforced RPTFE seat available

• Anti-static devices for ball-stem-body

• Fire safe design

• Floating type ball

• Flanged or butt welding ends

• ISO5211 Mounting pad

• Worm gear operator available

| Design standard | API 608/API 6D | | Fire safe standard | API 607 | | Connection | Flanged ends according to ASME B16.5, Butt welding ends to ASME B16.25 | | Nominal diameter | 1/2"-12" | | Pressure rating | ANSI Class150, ANSI Class300, ANSI Class600 | | Face to face | ASME B16.10 | | Temperature range | -20°C to +200°C | | Operation | Hand lever, Gear box |

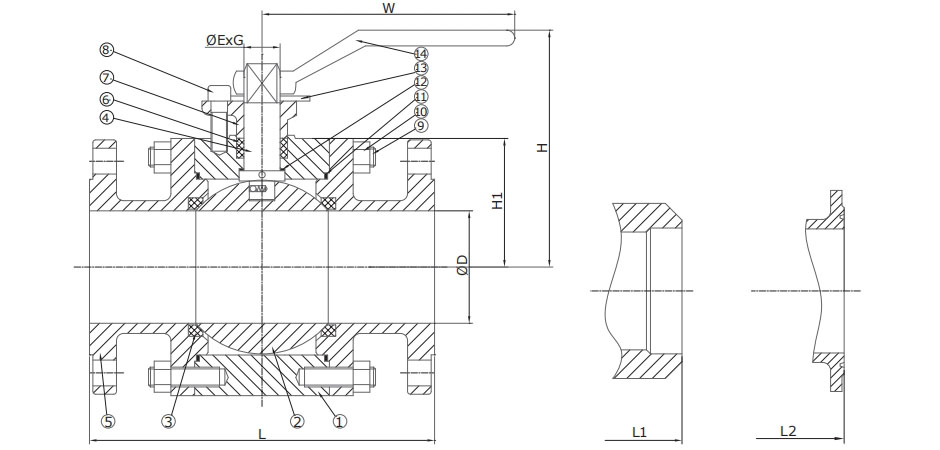

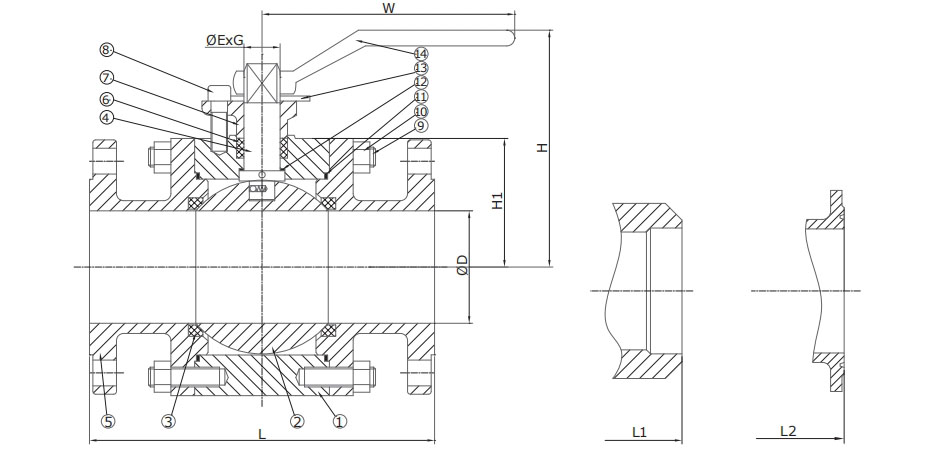

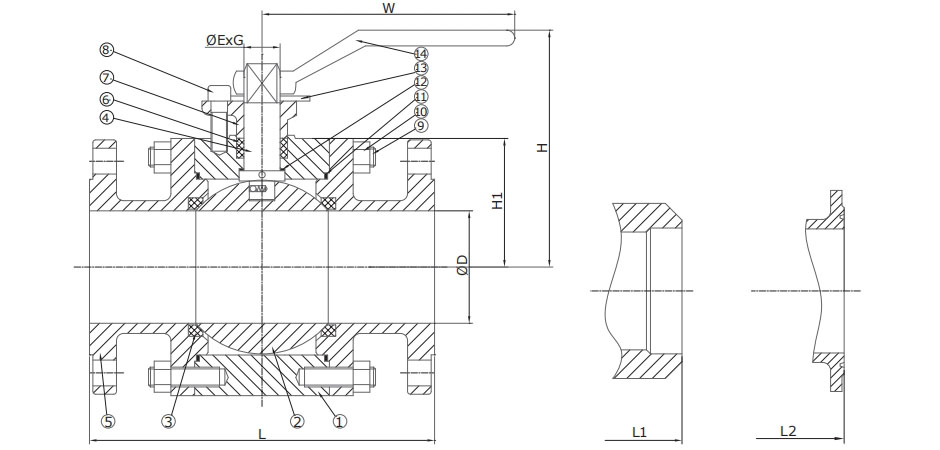

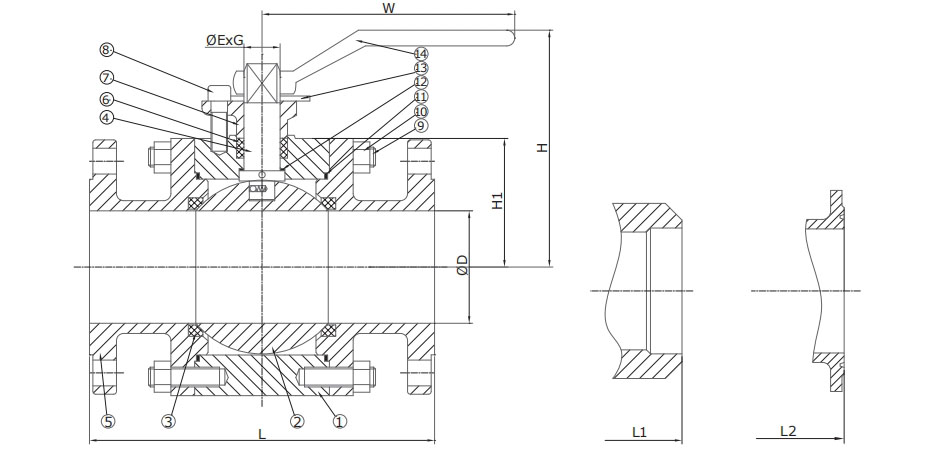

| No. | Part name | Material | | 1 | Body | A105 | F316 | LF2 | | 2 | Ball | F304 | F316 | F304 | | 3 | Seat | PTFE,RPTFE | | 4 | Stem | SS304 | SS316 | SS304 | | 5 | Bonnet | A105 | F316 | LF2 | | 6 | Packing | RPTFE | | 7 | Gland | A105 | F316 | LF2 | | 8 | Gland bolt | A193 B7 | A193 B8 | A193 B7 | | 9 | Bonnet stud | A193 B7 | A193 B8 | A320 L7 | | 10 | Bonnet stud nut | A194 2H | A194 8 | A194 4 | | 11 | Bonnet gasket | Graphite+304 | Graphite+316 | Graphite+316 | | 12 | Thrust washer | RPTFE | | 13 | Stop plate | Steel | SS304 | Steel | | 14 | Handle | Cast steel |

| SIZE | Class150 | Class150 WT(kg) | | DN | INCH | D | ExG | ISO5211 | H | H1 | L | L1 | W | RF | BW | | 15 | 1/2" | 15 | 12x8 | F03 | 55 | 38 | 108 | 140 | 200 | 3 | 2.6 | | 20 | 3/4" | 20 | 12x8 | F04 | 55 | 40 | 117 | 152 | 200 | 4 | 4 | | 25 | 1" | 25 | 14x9 | F05 | 65 | 44 | 127 | 165 | 300 | 6 | 5 | | 40 | 1 1/2" | 38 | 18x12 | F05 | 85 | 46 | 165 | 190 | 300 | 10 | 9 | | 50 | 2" | 49 | 20x14 | F07 | 100 | 60 | 178 | 216 | 400 | 13 | 12 | | 65 | 2 1/2" | 64 | 24x16 | F10 | 150 | 122 | 190 | 241 | 400 | 20 | 19 | | 80 | 3" | 76 | 24x16 | F10 | 180 | 145 | 203 | 283 | 600 | 26 | 28 | | 100 | 4" | 100 | 27x18 | F10 | 235 | 145 | 229 | 305 | 600 | 45 | 47 | | 150 | 6" | 150 | 32x22 | F14 | 250 | 170 | 394 | 457 | 600 | 126 | 131 | | 200 | 8" | 200 | | | 280 | 210 | 457 | 521 | 600 | 216 | 226 | | 250 | 10" | 250 | | | 320 | | 533 | 559 | 800 | 270 | 295 | | 300 | 12" | 300 | | | 390 | | 610 | 635 | 800 | 378 | 393 | | SIZE | Class300 | Class300 WT(kg) | | DN | INCH | D | ExG | ISO5211 | H | H1 | L | L1 | W | RF | BW | | 15 | 1/2" | 15 | 12x8 | F03 | 55 | 38 | 140 | 140 | 200 | 3.5 | 2.8 | | 20 | 3/4" | 20 | 12x8 | F04 | 55 | 40 | 152 | 152 | 200 | 4.6 | 3.1 | | 25 | 1" | 25 | 14x9 | F05 | 65 | 44 | 165 | 165 | 300 | 6.7 | 4.4 | | 40 | 1 1/2" | 38 | 18x12 | F05 | 85 | 46 | 190 | 190 | 300 | 10.5 | 5.5 | | 50 | 2" | 49 | 20x14 | F10 | 100 | 60 | 216 | 216 | 300 | 15 | 8.7 | | 65 | 2 1/2" | 64 | 24x16 | F10 | 150 | 122 | 241 | 241 | 300 | 22 | 13.5 | | 80 | 3" | 76 | 24x16 | F10 | 180 | 145 | 283 | 283 | 350 | 29 | 17 | | 100 | 4" | 100 | 27x18 | F12 | 235 | 145 | 305 | 305 | 480 | 50 | 31 | | 150 | 6" | 150 | 32x22 | F14 | 250 | 170 | 403 | 457 | 600 | 141 | 18 | | 200 | 8" | 200 | | | 280 | 210 | 502 | 521 | 600 | 242 | 194 | | 250 | 10" | 250 | | | 320 | | 568 | 559 | 800 | 302 | 234 | | 300 | 12" | 300 | | | 390 | | 648 | 635 | 800 | 423 | 325 |

| Design standard | API 608/API 6D | | Fire safe standard | API 607 | | Connection | Flanged ends according to ASME B16.5, Butt welding ends to ASME B16.25 | | Nominal diameter | 1/2"-12" | | Pressure rating | ANSI Class150, ANSI Class300, ANSI Class600 | | Face to face | ASME B16.10 | | Temperature range | -20°C to +200°C | | Operation | Hand lever, Gear box |

Series B53 forged body flanged ball valve is full bore designed according to API 608 and suitable for shutoff of various medium without much dirt such as air, gas, water, oil and liquids. FEATURES • Bolted bonnet and split body design Full bore for better Kv/Cv

• Blow-out-proof stem

• Both pure PTFE and 25% carbon fiber reinforced RPTFE seat available

• Anti-static devices for ball-stem-body

• Fire safe design

• Floating type ball

• Flanged or butt welding ends

• ISO5211 Mounting pad

• Worm gear operator available

| No. | Part name | Material | | 1 | Body | A105 | F316 | LF2 | | 2 | Ball | F304 | F316 | F304 | | 3 | Seat | PTFE,RPTFE | | 4 | Stem | SS304 | SS316 | SS304 | | 5 | Bonnet | A105 | F316 | LF2 | | 6 | Packing | RPTFE | | 7 | Gland | A105 | F316 | LF2 | | 8 | Gland bolt | A193 B7 | A193 B8 | A193 B7 | | 9 | Bonnet stud | A193 B7 | A193 B8 | A320 L7 | | 10 | Bonnet stud nut | A194 2H | A194 8 | A194 4 | | 11 | Bonnet gasket | Graphite+304 | Graphite+316 | Graphite+316 | | 12 | Thrust washer | RPTFE | | 13 | Stop plate | Steel | SS304 | Steel | | 14 | Handle | Cast steel |

| SIZE | Class150 | Class150 WT(kg) | | DN | INCH | D | ExG | ISO5211 | H | H1 | L | L1 | W | RF | BW | | 15 | 1/2" | 15 | 12x8 | F03 | 55 | 38 | 108 | 140 | 200 | 3 | 2.6 | | 20 | 3/4" | 20 | 12x8 | F04 | 55 | 40 | 117 | 152 | 200 | 4 | 4 | | 25 | 1" | 25 | 14x9 | F05 | 65 | 44 | 127 | 165 | 300 | 6 | 5 | | 40 | 1 1/2" | 38 | 18x12 | F05 | 85 | 46 | 165 | 190 | 300 | 10 | 9 | | 50 | 2" | 49 | 20x14 | F07 | 100 | 60 | 178 | 216 | 400 | 13 | 12 | | 65 | 2 1/2" | 64 | 24x16 | F10 | 150 | 122 | 190 | 241 | 400 | 20 | 19 | | 80 | 3" | 76 | 24x16 | F10 | 180 | 145 | 203 | 283 | 600 | 26 | 28 | | 100 | 4" | 100 | 27x18 | F10 | 235 | 145 | 229 | 305 | 600 | 45 | 47 | | 150 | 6" | 150 | 32x22 | F14 | 250 | 170 | 394 | 457 | 600 | 126 | 131 | | 200 | 8" | 200 | | | 280 | 210 | 457 | 521 | 600 | 216 | 226 | | 250 | 10" | 250 | | | 320 | | 533 | 559 | 800 | 270 | 295 | | 300 | 12" | 300 | | | 390 | | 610 | 635 | 800 | 378 | 393 | | SIZE | Class300 | Class300 WT(kg) | | DN | INCH | D | ExG | ISO5211 | H | H1 | L | L1 | W | RF | BW | | 15 | 1/2" | 15 | 12x8 | F03 | 55 | 38 | 140 | 140 | 200 | 3.5 | 2.8 | | 20 | 3/4" | 20 | 12x8 | F04 | 55 | 40 | 152 | 152 | 200 | 4.6 | 3.1 | | 25 | 1" | 25 | 14x9 | F05 | 65 | 44 | 165 | 165 | 300 | 6.7 | 4.4 | | 40 | 1 1/2" | 38 | 18x12 | F05 | 85 | 46 | 190 | 190 | 300 | 10.5 | 5.5 | | 50 | 2" | 49 | 20x14 | F10 | 100 | 60 | 216 | 216 | 300 | 15 | 8.7 | | 65 | 2 1/2" | 64 | 24x16 | F10 | 150 | 122 | 241 | 241 | 300 | 22 | 13.5 | | 80 | 3" | 76 | 24x16 | F10 | 180 | 145 | 283 | 283 | 350 | 29 | 17 | | 100 | 4" | 100 | 27x18 | F12 | 235 | 145 | 305 | 305 | 480 | 50 | 31 | | 150 | 6" | 150 | 32x22 | F14 | 250 | 170 | 403 | 457 | 600 | 141 | 18 | | 200 | 8" | 200 | | | 280 | 210 | 502 | 521 | 600 | 242 | 194 | | 250 | 10" | 250 | | | 320 | | 568 | 559 | 800 | 302 | 234 | | 300 | 12" | 300 | | | 390 | | 648 | 635 | 800 | 423 | 325 |

|

Forged Body Flanged Ball Valves ★★★★

Forged Body Flanged Ball Valves ★★★★