Series B63 forged body trunnion mounted ball valve is designed according to API 608 and suitable for shutoff of various mediums. Comparing to floating ball valve, when under pressure, the ball is stable in it’s position and the force push the seat toward the ball to form a tightness, all the load come to the stem and bearings. Therefore, the seat is protected and low torque, stable sealing, long life time is assured. Forged body makes the valve qualified for essential working condition. FEATURES • Bolted bonnet and three piece body Full bore for better Kv/Cv

• Blow-out-proof stem

• Pure PTFE, 25% carbon fiber reinforced RPTFE and metal seat available

• Anti-static devices for ball-stem-body

• Fire safe design

• Trunnion mounted ball type

• Flanged or butt welding ends

• Worm gear operator available

| Design standard | API 608/API 6D | | Fire safe standard | API 607 | | Connection | Flanged ends according to ASME B16.5, Butt welding ends to ASME B16.25 | | Nominal diameter | 2"-36" | | Pressure rating | ANSI Class150, ANSI Class300,ANSI Class600,ANSI Class900,ANSI Class1500,ANSI Class2500 | | Face to face | ASME B16.10 | | Temperature range | -20°C to +200°C for soft seat, -40°C to +360°C for metal seat | | Operation | Hand lever, Gear box |

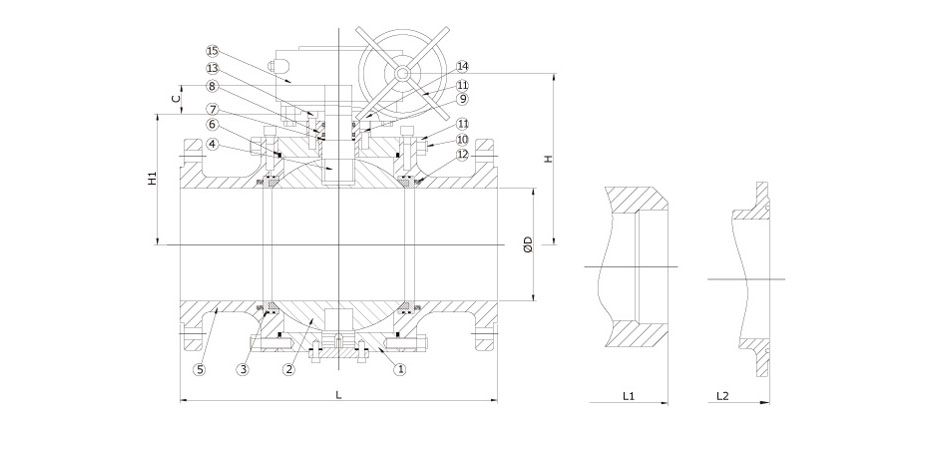

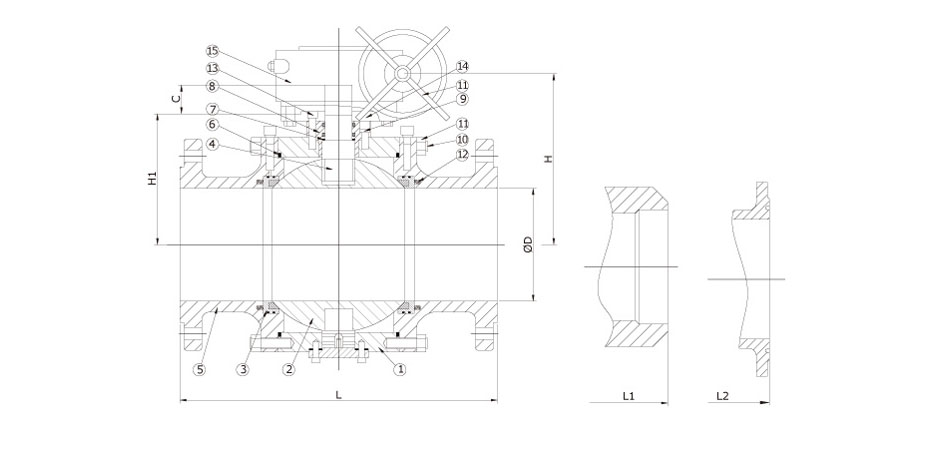

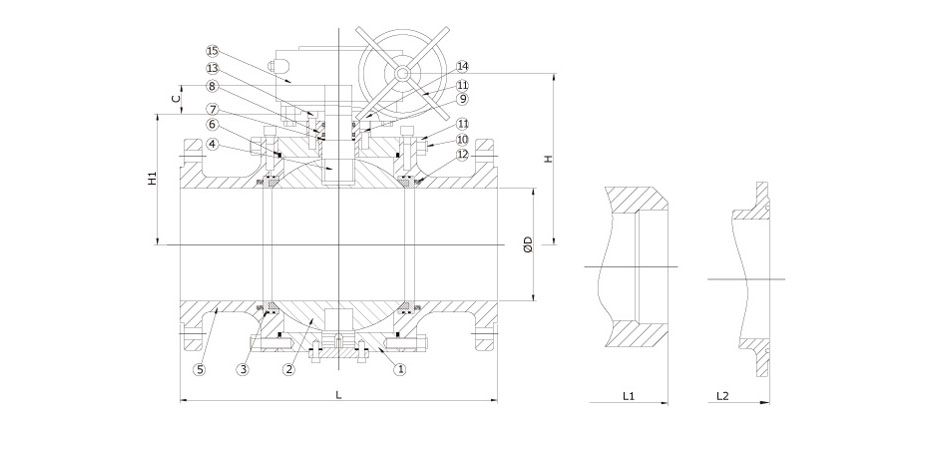

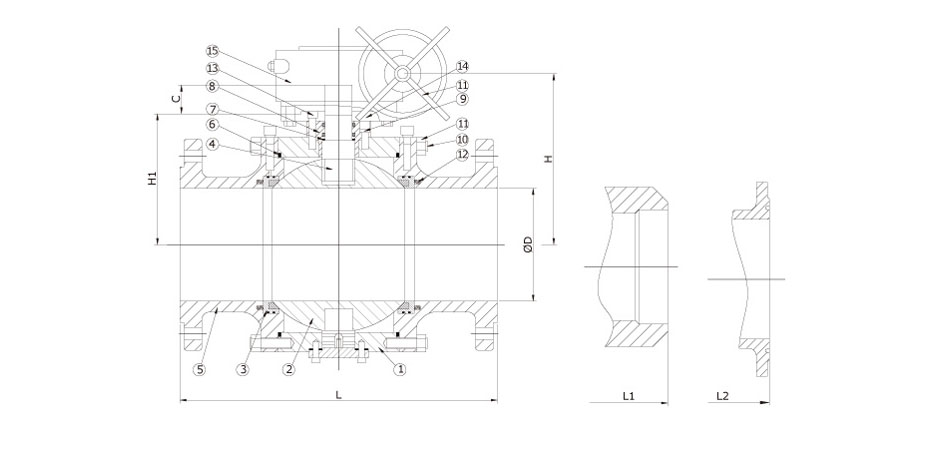

| No. | Part name | Material | | 1 | Body | A105 | F316 | LF2 | | 2 | Ball | F304 | F316 | F304 | | 3 | Seat set | PTFE, RPTFE, PEEK, Metal seat | | 4 | Stem | SS304 | SS316 | SS304 | | 5 | Bonnet | A105 | F316 | LF2 | | 6 | Bonnet gasket | Graphite+316 | | 7 | Packing set | RPTFE, Graphite | | 8 | Gland | SS316 | | 9 | Gland bolt | A193 B7 | A193 B8 | A193 B7 | | 10 | Bonnet stud | A193 B7 | A193 B8 | A320 L7 | | 11 | Bonnet stud nut | A194 2H | A194 8 | A194 4 | | 12 | Seat spring | SS304 | Inconel X-750 | SS304 | | 13 | Top flange bolt | A193 B7 | A193 B8 | A193 B7 | | 14 | Top flange | A105 | F316 | LF2 | | 15 | Gear box | Carbon steel shell |

| SIZE | Class150 | Class150

WT(kg) | Class300 | Class300

WT(kg) | | DN | INCH | D | C | E | F | H | H1 | L | L1 | RF | BW | D | C | E | F | H | H1 | L | L1 | RF/RTJ | BW | | 50 | 2" | 49 | 45 | 22 | F10 | 120 | 114 | 178 | 216 | 28 | 25 | 49 | 45 | 22 | F10 | 120 | 114 | 216 | 216 | 30 | 24 | | 65 | 2 1/2" | 64 | 50 | 24 | F10 | 150 | 120 | 190 | 241 | 35 | 28 | 64 | 50 | 24 | F10 | 150 | 120 | 241 | 241 | 40 | 31 | | 80 | 3" | 76 | 55 | 28 | F12 | 180 | 140 | 203 | 283 | 55 | 49 | 76 | 55 | 28 | F12 | 180 | 140 | 283 | 283 | 60 | 49 | | 100 | 4" | 100 | 55 | 32 | F12 | 235 | 164 | 229 | 305 | 80 | 71 | 100 | 55 | 32 | F12 | 235 | 164 | 305 | 305 | 90 | 72 | | 150 | 6" | 150 | 72 | 38 | F16 | 250 | 229 | 394 | 457 | 190 | 182 | 150 | 72 | 38 | F16 | 250 | 229 | 403 | 403 | 200 | 169 | | 200 | 8" | 200 | 81 | 50 | F25 | 280 | 275 | 457 | 521 | 290 | 277 | 200 | 81 | 50 | F25 | 280 | 275 | 502 | 521 | 325 | 280 | | 250 | 10" | 250 | 81 | 55 | F25 | 320 | 315 | 533 | 559 | 445 | 423 | 250 | 81 | 55 | F25 | 320 | 315 | 568 | 559 | 490 | 424 | | 300 | 12" | 300 | 110 | 63 | F25 | 390 | 355 | 610 | 635 | 570 | 553 | 300 | 110 | 63 | F25 | 390 | 355 | 648 | 635 | 690 | 598 | | 350 | 14" | 350 | 110 | 68 | F25 | 420 | 387 | 686 | 762 | 780 | 747 | 350 | 110 | 68 | F25 | 420 | 387 | 762 | 762 | 990 | 872 | | 400 | 16" | 400 | 115 | 78 | F25 | 555 | 436 | 762 | 838 | 1520 | 1481 | 400 | 115 | 78 | F25 | 555 | 436 | 838 | 838 | 1810 | 1665 | | 450 | 18" | 450 | 115 | 92 | F25 | 600 | 470 | 864 | 914 | 2300 | 2266 | 450 | 115 | 92 | F25 | 600 | 470 | 914 | 914 | 2620 | 2440 | | 500 | 20" | 500 | 115 | 98 | F30 | 635 | 525 | 914 | 991 | 2500 | 2460 | 500 | 115 | 98 | F30 | 635 | 525 | 991 | 991 | 2860 | 2635 | | 600 | 24" | 600 | 130 | 105 | F30 | 710 | 616 | 1067 | 1143 | 3950 | 3904 | 600 | 130 | 105 | F30 | 710 | 616 | 1143 | 1143 | 4430 | 4075 |

| Design standard | API 608/API 6D | | Fire safe standard | API 607 | | Connection | Flanged ends according to ASME B16.5, Butt welding ends to ASME B16.25 | | Nominal diameter | 2"-36" | | Pressure rating | ANSI Class150, ANSI Class300,ANSI Class600,ANSI Class900,ANSI Class1500,ANSI Class2500 | | Face to face | ASME B16.10 | | Temperature range | -20°C to +200°C for soft seat, -40°C to +360°C for metal seat | | Operation | Hand lever, Gear box |

Series B63 forged body trunnion mounted ball valve is designed according to API 608 and suitable for shutoff of various mediums. Comparing to floating ball valve, when under pressure, the ball is stable in it’s position and the force push the seat toward the ball to form a tightness, all the load come to the stem and bearings. Therefore, the seat is protected and low torque, stable sealing, long life time is assured. Forged body makes the valve qualified for essential working condition. FEATURES • Bolted bonnet and three piece body Full bore for better Kv/Cv

• Blow-out-proof stem

• Pure PTFE, 25% carbon fiber reinforced RPTFE and metal seat available

• Anti-static devices for ball-stem-body

• Fire safe design

• Trunnion mounted ball type

• Flanged or butt welding ends

• Worm gear operator available

| No. | Part name | Material | | 1 | Body | A105 | F316 | LF2 | | 2 | Ball | F304 | F316 | F304 | | 3 | Seat set | PTFE, RPTFE, PEEK, Metal seat | | 4 | Stem | SS304 | SS316 | SS304 | | 5 | Bonnet | A105 | F316 | LF2 | | 6 | Bonnet gasket | Graphite+316 | | 7 | Packing set | RPTFE, Graphite | | 8 | Gland | SS316 | | 9 | Gland bolt | A193 B7 | A193 B8 | A193 B7 | | 10 | Bonnet stud | A193 B7 | A193 B8 | A320 L7 | | 11 | Bonnet stud nut | A194 2H | A194 8 | A194 4 | | 12 | Seat spring | SS304 | Inconel X-750 | SS304 | | 13 | Top flange bolt | A193 B7 | A193 B8 | A193 B7 | | 14 | Top flange | A105 | F316 | LF2 | | 15 | Gear box | Carbon steel shell |

| SIZE | Class150 | Class150

WT(kg) | Class300 | Class300

WT(kg) | | DN | INCH | D | C | E | F | H | H1 | L | L1 | RF | BW | D | C | E | F | H | H1 | L | L1 | RF/RTJ | BW | | 50 | 2" | 49 | 45 | 22 | F10 | 120 | 114 | 178 | 216 | 28 | 25 | 49 | 45 | 22 | F10 | 120 | 114 | 216 | 216 | 30 | 24 | | 65 | 2 1/2" | 64 | 50 | 24 | F10 | 150 | 120 | 190 | 241 | 35 | 28 | 64 | 50 | 24 | F10 | 150 | 120 | 241 | 241 | 40 | 31 | | 80 | 3" | 76 | 55 | 28 | F12 | 180 | 140 | 203 | 283 | 55 | 49 | 76 | 55 | 28 | F12 | 180 | 140 | 283 | 283 | 60 | 49 | | 100 | 4" | 100 | 55 | 32 | F12 | 235 | 164 | 229 | 305 | 80 | 71 | 100 | 55 | 32 | F12 | 235 | 164 | 305 | 305 | 90 | 72 | | 150 | 6" | 150 | 72 | 38 | F16 | 250 | 229 | 394 | 457 | 190 | 182 | 150 | 72 | 38 | F16 | 250 | 229 | 403 | 403 | 200 | 169 | | 200 | 8" | 200 | 81 | 50 | F25 | 280 | 275 | 457 | 521 | 290 | 277 | 200 | 81 | 50 | F25 | 280 | 275 | 502 | 521 | 325 | 280 | | 250 | 10" | 250 | 81 | 55 | F25 | 320 | 315 | 533 | 559 | 445 | 423 | 250 | 81 | 55 | F25 | 320 | 315 | 568 | 559 | 490 | 424 | | 300 | 12" | 300 | 110 | 63 | F25 | 390 | 355 | 610 | 635 | 570 | 553 | 300 | 110 | 63 | F25 | 390 | 355 | 648 | 635 | 690 | 598 | | 350 | 14" | 350 | 110 | 68 | F25 | 420 | 387 | 686 | 762 | 780 | 747 | 350 | 110 | 68 | F25 | 420 | 387 | 762 | 762 | 990 | 872 | | 400 | 16" | 400 | 115 | 78 | F25 | 555 | 436 | 762 | 838 | 1520 | 1481 | 400 | 115 | 78 | F25 | 555 | 436 | 838 | 838 | 1810 | 1665 | | 450 | 18" | 450 | 115 | 92 | F25 | 600 | 470 | 864 | 914 | 2300 | 2266 | 450 | 115 | 92 | F25 | 600 | 470 | 914 | 914 | 2620 | 2440 | | 500 | 20" | 500 | 115 | 98 | F30 | 635 | 525 | 914 | 991 | 2500 | 2460 | 500 | 115 | 98 | F30 | 635 | 525 | 991 | 991 | 2860 | 2635 | | 600 | 24" | 600 | 130 | 105 | F30 | 710 | 616 | 1067 | 1143 | 3950 | 3904 | 600 | 130 | 105 | F30 | 710 | 616 | 1143 | 1143 | 4430 | 4075 |

|

Forged Body Trunnion Mounted Ball Valves ★★★★

Forged Body Trunnion Mounted Ball Valves ★★★★