Series C11 wafer lift check valve opens when the opening force exceeds the closing force. The opening force depends on the pressure or the flow volume and the closing force on the tension of the closing spring, the closing weight, the installation position and the size of the check valve. The wafer design drastically reduces the weight in comparison with conventional valves.

They have been widely used in Marine and offshore industry, Petrochemical industry, Pharmaceutical industry, Heating and cooling, Ventilation, Fir protection systems, Water industry, Beer and beverage industry. FEATURES • Wafer short face-to-face dimension• Self-centering

• Low pressure drops

• Easy to install and maintenance

• Can be installed on vertical pipelines with down flow

| Connection | Wafer | | Nominal diameter | DN50-DN600 | | Pressure rating | ANSI CLASS300, ANSI CLASS600, ANSI CLASS900, ANSI CLASS1500 | | Face to face | API 594 | | Coating on steel body | Painting system B |

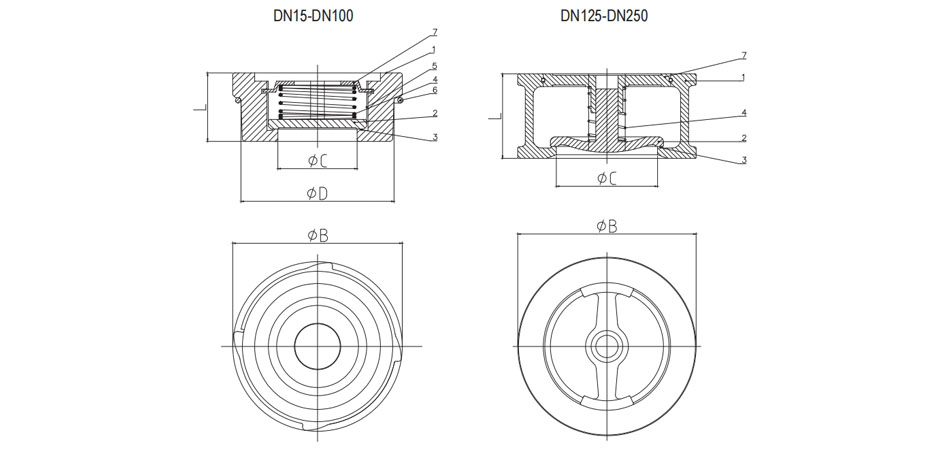

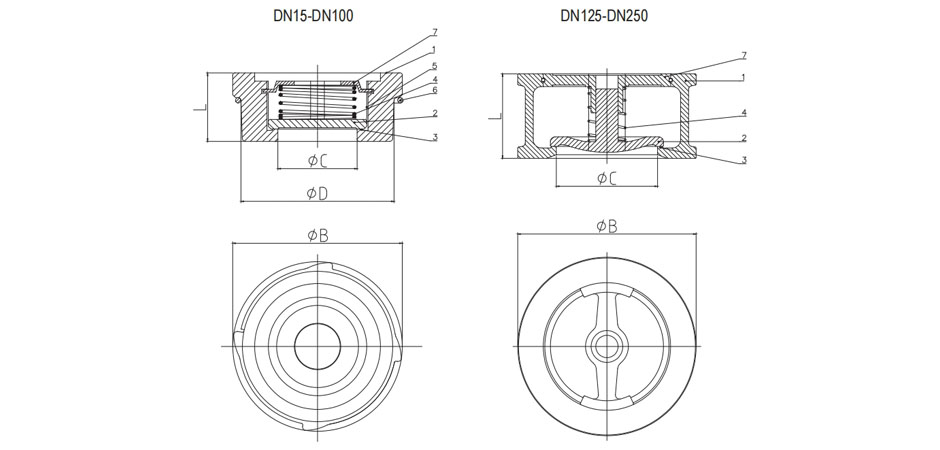

| No. | Part name | Material | | 1 | Body | Galvanized steel,SS316L | | 2 | Disc | SS304,SS316L,SS304/SS316+EPDM/NBR/VITON | | 3 | Seat | SS316L | | 4 | Spring | SS321 | | 5 | Guider | SS316L | | 6 | Ring | SS316L | | 7 | Bushing | SS316L | | 8 | Screws | SS316L |

| SIZE | B | C | D | L | WT(kg) | | DN | INCH | | 15 | 1/2" | 60 | 15 | 43 | 16 | 0.1 | | 20 | 3/4" | 74 | 20 | 49 | 19 | 0.2 | | 25 | 1" | 85 | 25 | 61 | 22 | 0.3 | | 32 | 1 1/4" | 95 | 32 | 69 | 28 | 0.4 | | 40 | 1 1/2" | 104 | 39 | 78 | 32 | 0.5 | | 50 | 2" | 120 | 48 | 98 | 40 | 1.1 | | 65 | 2 1/2" | 140 | 63 | 115 | 46 | 1.5 | | 80 | 3" | 161 | 76 | 137 | 50 | 2.3 | | 100 | 4" | 186 | 90 | 158 | 60 | 3.5 | | 125 | 5" | - | 112 | 194 | 90 | 5.9 | | 150 | 6" | - | 135 | 220 | 106 | 8.3 | | 200 | 8" | - | 180 | 275 | 140 | 15.4 |

| Connection | Wafer | | Nominal diameter | DN50-DN600 | | Pressure rating | ANSI CLASS300, ANSI CLASS600, ANSI CLASS900, ANSI CLASS1500 | | Face to face | API 594 | | Coating on steel body | Painting system B |

Series C11 wafer lift check valve opens when the opening force exceeds the closing force. The opening force depends on the pressure or the flow volume and the closing force on the tension of the closing spring, the closing weight, the installation position and the size of the check valve. The wafer design drastically reduces the weight in comparison with conventional valves.

They have been widely used in Marine and offshore industry, Petrochemical industry, Pharmaceutical industry, Heating and cooling, Ventilation, Fir protection systems, Water industry, Beer and beverage industry. FEATURES • Wafer short face-to-face dimension• Self-centering

• Low pressure drops

• Easy to install and maintenance

• Can be installed on vertical pipelines with down flow

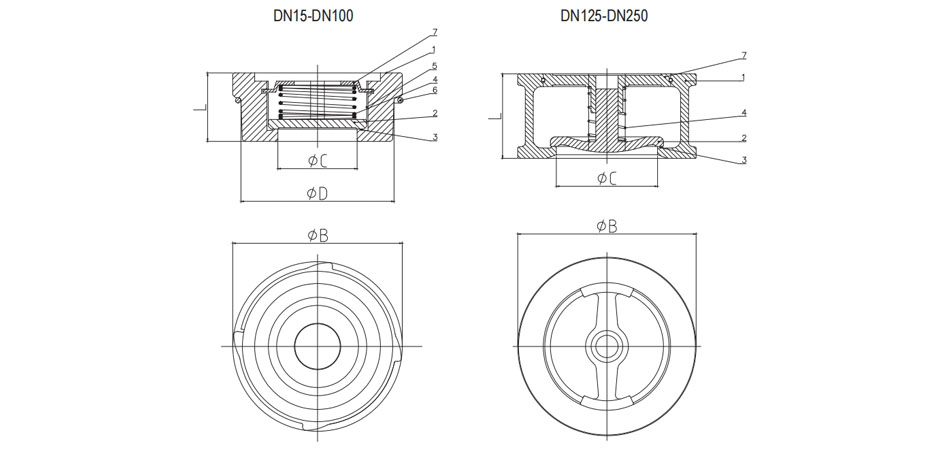

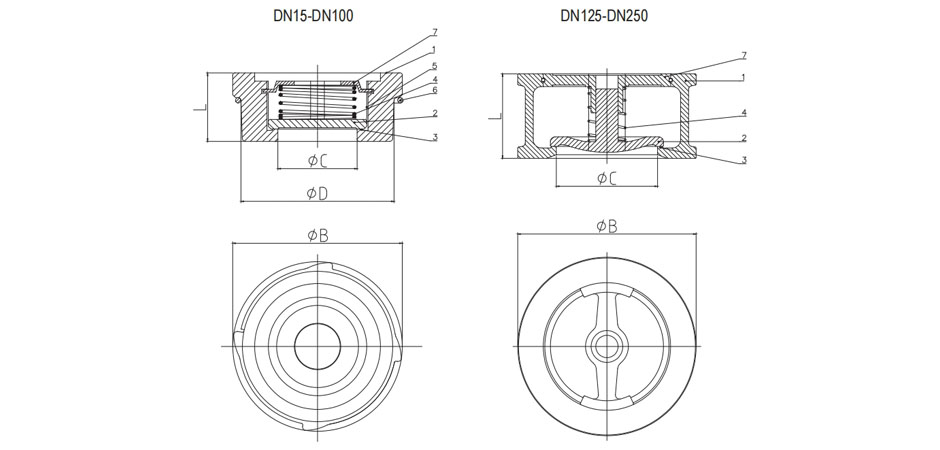

| No. | Part name | Material | | 1 | Body | Galvanized steel,SS316L | | 2 | Disc | SS304,SS316L,SS304/SS316+EPDM/NBR/VITON | | 3 | Seat | SS316L | | 4 | Spring | SS321 | | 5 | Guider | SS316L | | 6 | Ring | SS316L | | 7 | Bushing | SS316L | | 8 | Screws | SS316L |

| SIZE | B | C | D | L | WT(kg) | | DN | INCH | | 15 | 1/2" | 60 | 15 | 43 | 16 | 0.1 | | 20 | 3/4" | 74 | 20 | 49 | 19 | 0.2 | | 25 | 1" | 85 | 25 | 61 | 22 | 0.3 | | 32 | 1 1/4" | 95 | 32 | 69 | 28 | 0.4 | | 40 | 1 1/2" | 104 | 39 | 78 | 32 | 0.5 | | 50 | 2" | 120 | 48 | 98 | 40 | 1.1 | | 65 | 2 1/2" | 140 | 63 | 115 | 46 | 1.5 | | 80 | 3" | 161 | 76 | 137 | 50 | 2.3 | | 100 | 4" | 186 | 90 | 158 | 60 | 3.5 | | 125 | 5" | - | 112 | 194 | 90 | 5.9 | | 150 | 6" | - | 135 | 220 | 106 | 8.3 | | 200 | 8" | - | 180 | 275 | 140 | 15.4 |

|