Series A45 double flanged butterfly valve features a bonded liner extending over the flanges. The double flange design is suitable for high pressure loading and for use in heavy industry, shipbuilding, severe vacuum applications and water treatment industry like potable water, water treatment and wastewater applications. FEATURES • ISO5211 top flange together with stem heat suitable for direct mounting of actuators

• Stem anti-blowout design keep safety in field use

• Bonded seat protects the body and shaft out of contact with medium

• No exposed pins or bolts for stem-to-disc connection

• Single flange mounting is possible

• Can be installed in any desired position

• Bubble-tight shut off at full pressure rating

• Large flow capacity and enough strength

| Connection | Wafer | | Nominal diameter | DN50-DN2200 | | Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2200 | | Flange accommodation | EN1092 PN10/16, ASME B16.5 Class150 | | Face to face | EN558 Series 13 | | Top flange | ISO 5211 | | Tightness check | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40°C to +130°C (Depending on pressure, medium and material) | | Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

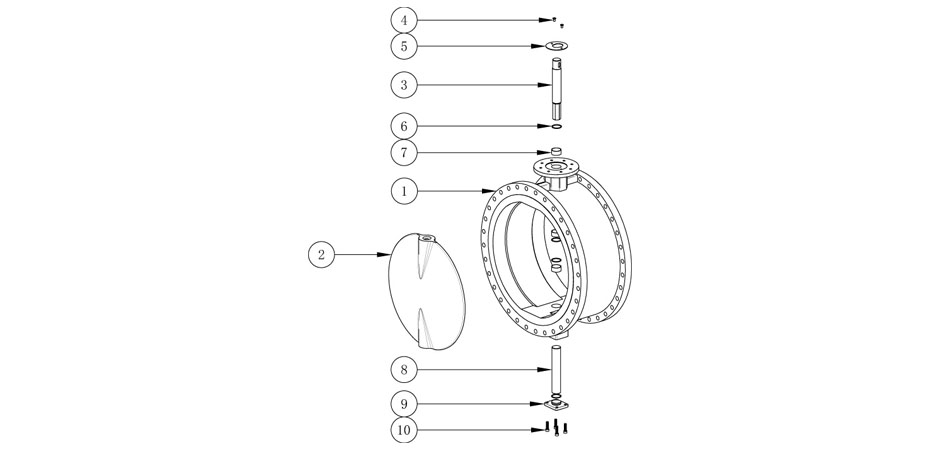

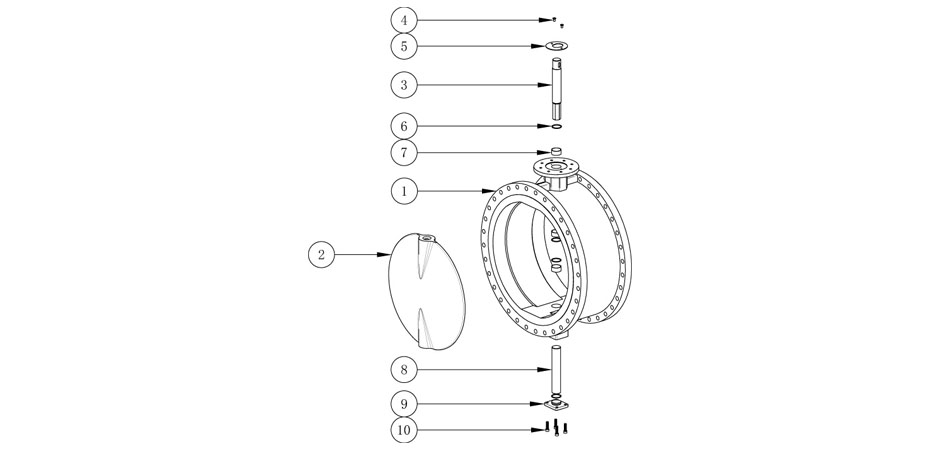

| No. | Part name | Material | | 1 | Body | ASTM A536 65-45-12, WCB, CF8M bonded with NBR or EPDM | | 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 | | 3 | Stem | SS420, SS431 | | 4 | Screw | SS304 | | 5 | Retainer | SS201 | | 6 | Weather seal | NBR | | 7 | Bearing | RPTFE with Graphite on I.D. | | 8 | Lower Stem | SS420, SS431 | | 9 | Bottom cover | Same as body | | 10 | Bolt | SS304 |

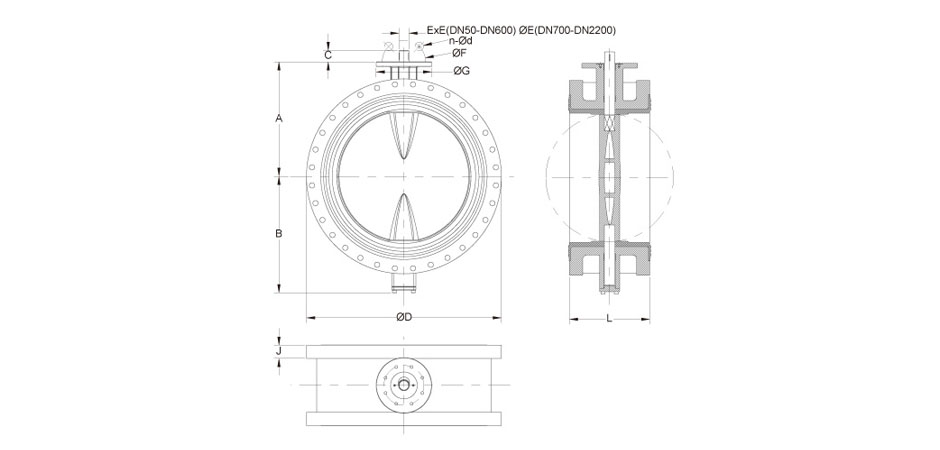

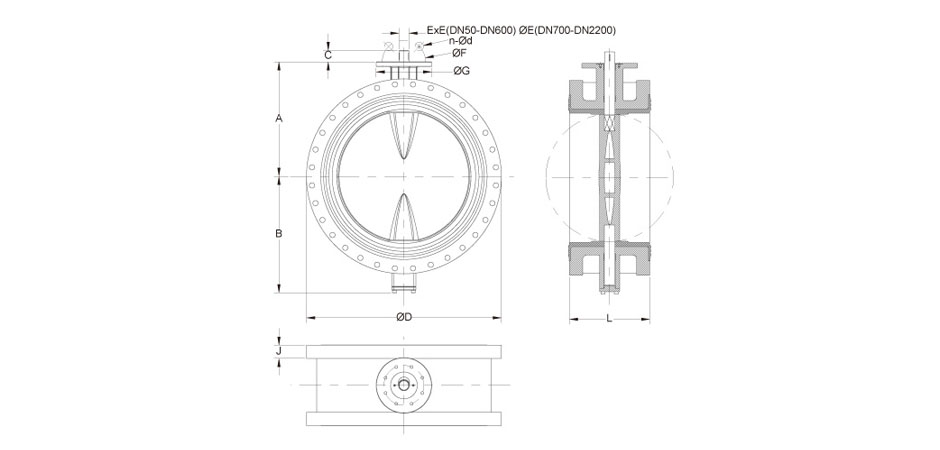

| SIZE | A | B | C | D | E | F | n | d | G | J | L | WT(kg) | | DN | INCH | | 50 | 2" | 142 | 80 | 13.5 | 165 | 9 | 50 | 4 | 8 | 70 | 15 | 108 | 9 | | 65 | 2 1/2" | 155 | 89 | 13.5 | 185 | 9 | 50 | 4 | 8 | 70 | 15 | 112 | 10 | | 80 | 3" | 161 | 95 | 13.5 | 200 | 9 | 50 | 4 | 8 | 70 | 17 | 114 | 12 | | 100 | 4" | 180 | 114 | 13.5 | 229 | 11 | 70 | 4 | 10 | 90 | 17 | 127 | 16 | | 125 | 5" | 193 | 127 | 17.5 | 254 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 24 | | 150 | 6" | 205 | 139 | 17.5 | 285 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 29 | | 200 | 8" | 250 | 175 | 24.5 | 343 | 17 | 102 | 4 | 12 | 125 | 21 | 152 | 39 | | 250 | 10" | 282 | 203 | 25 | 406 | 22 | 102 | 4 | 12 | 125 | 23 | 165 | 60 | | 300 | 12" | 326 | 242 | 25 | 483 | 22 | 102 | 4 | 12 | 125 | 24 | 178 | 82 | | 350 | 14" | 358 | 267 | 30 | 533 | 27 | 125 | 4 | 14 | 150 | 24 | 190 | 108 | | 400 | 16" | 380 | 301 | 30 | 597 | 27 | 125 | 4 | 14 | 150 | 28 | 216 | 145 | | 450 | 18" | 422 | 381 | 39 | 640 | 36 | 140 | 4 | 18 | 175 | 33 | 222 | 183 | | 500 | 20" | 479 | 387 | 39 | 710 | 36 | 140 | 4 | 18 | 175 | 40 | 229 | 230 | | 600 | 24" | 562 | 457 | 49 | 840 | 46 | 165 | 4 | 22 | 210 | 40 | 267 | 303 | | 700 | 28" | 560 | 465 | 95 | 910 | 63.35 | 254 | 8 | 18 | 300 | 40 | 292 | 410 | | 750 | 30" | 610 | 508 | 95 | 984 | 63.35 | 254 | 8 | 18 | 300 | 43 | 308 | 552 | | 800 | 32" | 620 | 519 | 95 | 1025 | 63.35 | 254 | 8 | 18 | 300 | 43 | 318 | 610 | | 900 | 36" | 692 | 576 | 130 | 1125 | 75 | 254 | 8 | 18 | 300 | 46 | 330 | 750 | | 1000 | 40" | 735 | 640 | 130 | 1255 | 85 | 254 | 8 | 22 | 300 | 50 | 410 | 945 | | 1100 | 44" | 813 | 735 | 150 | 1355 | 85 | 254 | 8 | 22 | 300 | 53 | 450 | 1120 | | 1200 | 48" | 917 | 783 | 150 | 1485 | 105 | 298 | 8 | 22 | 350 | 57 | 470 | 1350 | | 1400 | 56" | 1000 | 925 | 200 | 1685 | 120 | 356 | 8 | 32 | 415 | 60 | 530 | 1700 | | 1500 | 60" | 1050 | 950 | 200 | 1820 | 140 | 356 | 8 | 32 | 415 | 78 | 570 | 2000 | | 1600 | 64" | 1150 | 1045 | 200 | 1930 | 140 | 356 | 8 | 32 | 415 | 65 | 600 | 2500 | | 1800 | 72" | 1260 | 1156 | 280 | 2130 | 160 | 406 | 8 | 40 | 475 | 70 | 670 | 3500 | | 2000 | 80" | 1363 | 1350 | 280 | 2345 | 160 | 406 | 8 | 40 | 475 | 75 | 760 | 4000 | | 2200 | 88" | 1500 | 1430 | 300 | 2555 | 180 | 483 | 12 | 40 | 560 | 85 | 636 | 4500 |

| Connection | Wafer | | Nominal diameter | DN50-DN2200 | | Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2200 | | Flange accommodation | EN1092 PN10/16, ASME B16.5 Class150 | | Face to face | EN558 Series 13 | | Top flange | ISO 5211 | | Tightness check | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40°C to +130°C (Depending on pressure, medium and material) | | Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

Series A45 double flanged butterfly valve features a bonded liner extending over the flanges. The double flange design is suitable for high pressure loading and for use in heavy industry, shipbuilding, severe vacuum applications and water treatment industry like potable water, water treatment and wastewater applications. FEATURES • ISO5211 top flange together with stem heat suitable for direct mounting of actuators

• Stem anti-blowout design keep safety in field use

• Bonded seat protects the body and shaft out of contact with medium

• No exposed pins or bolts for stem-to-disc connection

• Single flange mounting is possible

• Can be installed in any desired position

• Bubble-tight shut off at full pressure rating

• Large flow capacity and enough strength

| No. | Part name | Material | | 1 | Body | ASTM A536 65-45-12, WCB, CF8M bonded with NBR or EPDM | | 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 | | 3 | Stem | SS420, SS431 | | 4 | Screw | SS304 | | 5 | Retainer | SS201 | | 6 | Weather seal | NBR | | 7 | Bearing | RPTFE with Graphite on I.D. | | 8 | Lower Stem | SS420, SS431 | | 9 | Bottom cover | Same as body | | 10 | Bolt | SS304 |

| SIZE | A | B | C | D | E | F | n | d | G | J | L | WT(kg) | | DN | INCH | | 50 | 2" | 142 | 80 | 13.5 | 165 | 9 | 50 | 4 | 8 | 70 | 15 | 108 | 9 | | 65 | 2 1/2" | 155 | 89 | 13.5 | 185 | 9 | 50 | 4 | 8 | 70 | 15 | 112 | 10 | | 80 | 3" | 161 | 95 | 13.5 | 200 | 9 | 50 | 4 | 8 | 70 | 17 | 114 | 12 | | 100 | 4" | 180 | 114 | 13.5 | 229 | 11 | 70 | 4 | 10 | 90 | 17 | 127 | 16 | | 125 | 5" | 193 | 127 | 17.5 | 254 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 24 | | 150 | 6" | 205 | 139 | 17.5 | 285 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 29 | | 200 | 8" | 250 | 175 | 24.5 | 343 | 17 | 102 | 4 | 12 | 125 | 21 | 152 | 39 | | 250 | 10" | 282 | 203 | 25 | 406 | 22 | 102 | 4 | 12 | 125 | 23 | 165 | 60 | | 300 | 12" | 326 | 242 | 25 | 483 | 22 | 102 | 4 | 12 | 125 | 24 | 178 | 82 | | 350 | 14" | 358 | 267 | 30 | 533 | 27 | 125 | 4 | 14 | 150 | 24 | 190 | 108 | | 400 | 16" | 380 | 301 | 30 | 597 | 27 | 125 | 4 | 14 | 150 | 28 | 216 | 145 | | 450 | 18" | 422 | 381 | 39 | 640 | 36 | 140 | 4 | 18 | 175 | 33 | 222 | 183 | | 500 | 20" | 479 | 387 | 39 | 710 | 36 | 140 | 4 | 18 | 175 | 40 | 229 | 230 | | 600 | 24" | 562 | 457 | 49 | 840 | 46 | 165 | 4 | 22 | 210 | 40 | 267 | 303 | | 700 | 28" | 560 | 465 | 95 | 910 | 63.35 | 254 | 8 | 18 | 300 | 40 | 292 | 410 | | 750 | 30" | 610 | 508 | 95 | 984 | 63.35 | 254 | 8 | 18 | 300 | 43 | 308 | 552 | | 800 | 32" | 620 | 519 | 95 | 1025 | 63.35 | 254 | 8 | 18 | 300 | 43 | 318 | 610 | | 900 | 36" | 692 | 576 | 130 | 1125 | 75 | 254 | 8 | 18 | 300 | 46 | 330 | 750 | | 1000 | 40" | 735 | 640 | 130 | 1255 | 85 | 254 | 8 | 22 | 300 | 50 | 410 | 945 | | 1100 | 44" | 813 | 735 | 150 | 1355 | 85 | 254 | 8 | 22 | 300 | 53 | 450 | 1120 | | 1200 | 48" | 917 | 783 | 150 | 1485 | 105 | 298 | 8 | 22 | 350 | 57 | 470 | 1350 | | 1400 | 56" | 1000 | 925 | 200 | 1685 | 120 | 356 | 8 | 32 | 415 | 60 | 530 | 1700 | | 1500 | 60" | 1050 | 950 | 200 | 1820 | 140 | 356 | 8 | 32 | 415 | 78 | 570 | 2000 | | 1600 | 64" | 1150 | 1045 | 200 | 1930 | 140 | 356 | 8 | 32 | 415 | 65 | 600 | 2500 | | 1800 | 72" | 1260 | 1156 | 280 | 2130 | 160 | 406 | 8 | 40 | 475 | 70 | 670 | 3500 | | 2000 | 80" | 1363 | 1350 | 280 | 2345 | 160 | 406 | 8 | 40 | 475 | 75 | 760 | 4000 | | 2200 | 88" | 1500 | 1430 | 300 | 2555 | 180 | 483 | 12 | 40 | 560 | 85 | 636 | 4500 |

|

Double Flanged Butterfly Valves ★★★★

Double Flanged Butterfly Valves ★★★★