Series A74 Lug high performance butterfly valve provides a cost-effective solution for a wide range of applications where bubble-tight shut-off is required. Utilizing an eccentric disc and offset shaft, the design incorporates the flexible-lip sealing system into a lightweight, compact body. The result is that in many cases the valve can replace globe valve and gate valve yet easier operating, longer lasting and lower cost. Significant performance makes the valve widely used in many applications such as Airport refueling, Hydrocarbon processing, HVAC, Air treatment, Chemical processing, Purified gas, Steam and vacuum services, Potable water, Powder and pulp processing, etc.

Lug design makes the valve convenient for connection between flanges and well used in end of pipe. FEATURES • One-piece stem design with ISO 5211 square drive

• ISO 5211 direct mounting flange on the valve body

• Easy-adjust gland packing accessible with actuator mounted in place

• Belleville washers on the gland nut offer reliable primary sealing between shaft and packing

• Retaining ring for both equably pressing on packing and stem blowout proof

• Multiply rows of RPTFE chevron for soft seat valve and Graphite chevron for fire safe and metallic seat

• Extended neck for pipe insulation

• Self-energized seat resulting in longer life and reduced maintenance Pin-less shaft to disc connection makes the valve convenient for parts replacement and reliable even under corrosion

• Seat retainer supports the seat and allows for easy changeout

• Double offset disc reducing the valve torque

• Alloy harden disc surface for metal seat increases the sealing life time

• Integral disc stop prevent disc from over travel

• Soft seat, fire safe seat and metallic seat are replaceable each other

• PTFE lined SS316 bearing support stem and increase service life

• Thrust ring for anti-blowout and anti-static

| Connection | Lug | | Size | 3"-24" | | Pressure | Class150,Class300 | | Flange standard | ASME B16.5 Class150,Class300; EN1092 PN16, PN25, PN40 | | Face to face | API 609 Category B valve Wafer | | Pressure test | API 598 | | Temperature | PTFE seat -29°C to +200°C,metal seat -29°C to +400°C | | Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

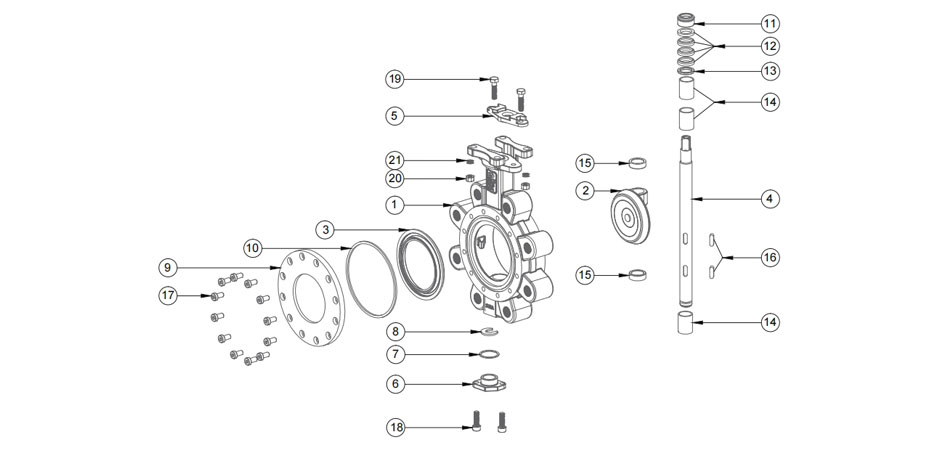

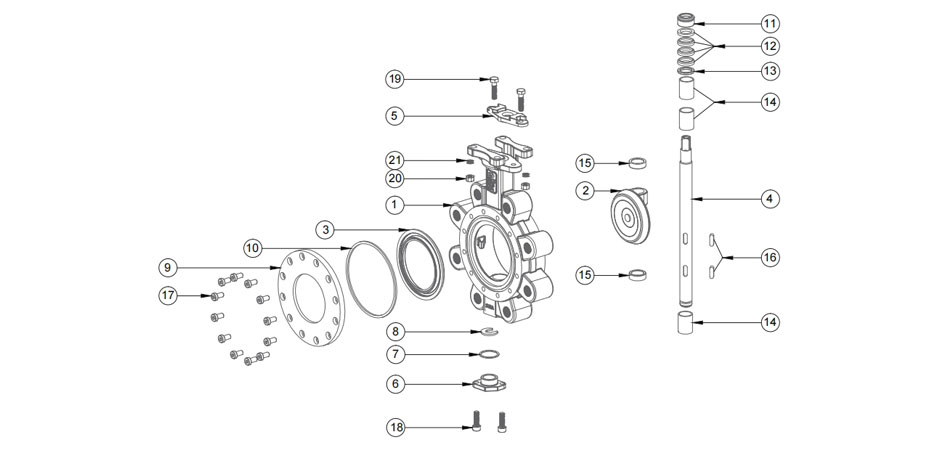

| No. | Part name | Material | | 1 | Body | WCB | CF8M | | 2 | Disc | CF8* | CF8M* | | 3 | Seat | RPTFE,SS316+RPTFE,SS316 | | 4 | Shaft | 17-4 PHSS,1.4462 | | 5 | Packing gland | CF8 | | 6 | Bottom cover | Same as body | | 7 | Cover seal | Graphite | | 8 | Thrust washer | SS316 | | 9 | Seat retainer | WCB | CF8M | | 10 | Gasket | RPTFE, Graphite | | 11 | Retaining ring | SS304 | | 12 | Packing | RPTFE, Graphite | | 13 | Packing ring | SS316 | | | 14 | Bearing | SS316+PTFE | | | 15 | Thrust bearing | SS316 | | | 16 | Key | SS316 | | 17 | Bolt | SS316 | | 18 | Bolt | SS304 | | 19 | Bolt | SS304 | | 20 | Nut | SS304 | | 21 | Belleville washer | SS304 | | *Supersonic spray welding of different materials on sealing surface of metal seating valve according to requirements |

| SIZE | A | B | C | D | D1 | E | Top

Flange | G | L | WT

(kg) | A | B | C | D | D1 | E | Top

Flange | G | L | WT

(kg) | | DN | INCH | Class150 | Class300 | | 50 | 2" | 126 | 79 | 13.5 | 92 | 123 | 11 | F05 | 45 | 43 | 5 | 126 | 79 | 13.5 | 92 | 155 | 11 | F05 | 45 | 43 | 6 | | 65 | 2 1/2" | 126 | 87 | 13.5 | 105 | 150 | 11 | F05 | 45 | 46 | 6 | 126 | 87 | 13.5 | 105 | 178 | 11 | F05 | 45 | 46 | 7 | | 80 | 3" | 145 | 100 | 17.5 | 130 | 156 | 11 | F07 | 72 | 48 | 8 | 145 | 100 | 17.5 | 130 | 199 | 11 | F07 | 72 | 48 | 10 | | 100 | 4" | 170 | 124 | 17.5 | 157 | 218 | 14 | F07 | 91 | 54 | 10 | 170 | 124 | 17.5 | 157 | 243 | 14 | F07 | 91 | 54 | 12 | | 125 | 5" | 185 | 144 | 17.5 | 186 | 241 | 14 | F07 | 114 | 57 | 15 | 185 | 144 | 17.5 | 186 | 265 | 14 | F07 | 114 | 57 | 18 | | 150 | 6" | 203 | 150 | 18.5 | 216 | 264 | 17 | F10 | 145 | 57 | 20 | 203 | 150 | 18.5 | 216 | 312 | 17 | F10 | 145 | 57 | 25 | | 200 | 8" | 239 | 186 | 24.5 | 269 | 325 | 22 | F10 | 192 | 64 | 23 | 257 | 204 | 24.5 | 269 | 370 | 22 | F10 | 192 | 73 | 40 | | 250 | 10" | 275 | 226 | 24.5 | 324 | 394 | 22 | F10 | 240 | 71 | 42 | 288 | 238 | 30 | 324 | 438 | 27 | F12 | 240 | 83 | 65 | | 300 | 12" | 307 | 251 | 30 | 380 | 471 | 27 | F12 | 285 | 81 | 60 | 330 | 268 | 30 | 380 | 512 | 27 | F12 | 285 | 92 | 100 | | 350 | 14" | 337 | 294 | 30 | 416 | 520 | 27 | F12 | 328 | 92 | 100 | 337 | 294 | 39 | 416 | 579 | 36 | F14 | 320 | 117 | 200 | | 400 | 16" | 368 | 320 | 30 | 476 | 585 | 27 | F14 | 373 | 102 | 155 | 368 | 320 | 49 | 476 | 643 | 46 | F16 | 363 | 133 | 260 | | 450 | 18" | 406 | 341 | 39 | 534 | 625 | 36 | F16 | 422 | 114 | 200 | 406 | 341 | 49 | 534 | 705 | 46 | F16 | 400 | 149 | 380 | | 500 | 20" | 442 | 383 | 49 | 588 | 693 | 46 | F16 | 470 | 127 | 270 | 442 | 383 | 49 | 588 | 769 | 46 | F25 | 450 | 159 | 470 | | 600 | 24" | 493 | 442 | 49 | 692 | 807 | 46 | F25 | 570 | 154 | 420 | 500 | 442 | 58 | 692 | 908 | 55 | F25 | 550 | 181 | 780 |

| Connection | Lug | | Size | 3"-24" | | Pressure | Class150,Class300 | | Flange standard | ASME B16.5 Class150,Class300; EN1092 PN16, PN25, PN40 | | Face to face | API 609 Category B valve Wafer | | Pressure test | API 598 | | Temperature | PTFE seat -29°C to +200°C,metal seat -29°C to +400°C | | Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

Series A74 Lug high performance butterfly valve provides a cost-effective solution for a wide range of applications where bubble-tight shut-off is required. Utilizing an eccentric disc and offset shaft, the design incorporates the flexible-lip sealing system into a lightweight, compact body. The result is that in many cases the valve can replace globe valve and gate valve yet easier operating, longer lasting and lower cost. Significant performance makes the valve widely used in many applications such as Airport refueling, Hydrocarbon processing, HVAC, Air treatment, Chemical processing, Purified gas, Steam and vacuum services, Potable water, Powder and pulp processing, etc.

Lug design makes the valve convenient for connection between flanges and well used in end of pipe. FEATURES • One-piece stem design with ISO 5211 square drive

• ISO 5211 direct mounting flange on the valve body

• Easy-adjust gland packing accessible with actuator mounted in place

• Belleville washers on the gland nut offer reliable primary sealing between shaft and packing

• Retaining ring for both equably pressing on packing and stem blowout proof

• Multiply rows of RPTFE chevron for soft seat valve and Graphite chevron for fire safe and metallic seat

• Extended neck for pipe insulation

• Self-energized seat resulting in longer life and reduced maintenance Pin-less shaft to disc connection makes the valve convenient for parts replacement and reliable even under corrosion

• Seat retainer supports the seat and allows for easy changeout

• Double offset disc reducing the valve torque

• Alloy harden disc surface for metal seat increases the sealing life time

• Integral disc stop prevent disc from over travel

• Soft seat, fire safe seat and metallic seat are replaceable each other

• PTFE lined SS316 bearing support stem and increase service life

• Thrust ring for anti-blowout and anti-static

| No. | Part name | Material | | 1 | Body | WCB | CF8M | | 2 | Disc | CF8* | CF8M* | | 3 | Seat | RPTFE,SS316+RPTFE,SS316 | | 4 | Shaft | 17-4 PHSS,1.4462 | | 5 | Packing gland | CF8 | | 6 | Bottom cover | Same as body | | 7 | Cover seal | Graphite | | 8 | Thrust washer | SS316 | | 9 | Seat retainer | WCB | CF8M | | 10 | Gasket | RPTFE, Graphite | | 11 | Retaining ring | SS304 | | 12 | Packing | RPTFE, Graphite | | 13 | Packing ring | SS316 | | | 14 | Bearing | SS316+PTFE | | | 15 | Thrust bearing | SS316 | | | 16 | Key | SS316 | | 17 | Bolt | SS316 | | 18 | Bolt | SS304 | | 19 | Bolt | SS304 | | 20 | Nut | SS304 | | 21 | Belleville washer | SS304 | | *Supersonic spray welding of different materials on sealing surface of metal seating valve according to requirements |

| SIZE | A | B | C | D | D1 | E | Top

Flange | G | L | WT

(kg) | A | B | C | D | D1 | E | Top

Flange | G | L | WT

(kg) | | DN | INCH | Class150 | Class300 | | 50 | 2" | 126 | 79 | 13.5 | 92 | 123 | 11 | F05 | 45 | 43 | 5 | 126 | 79 | 13.5 | 92 | 155 | 11 | F05 | 45 | 43 | 6 | | 65 | 2 1/2" | 126 | 87 | 13.5 | 105 | 150 | 11 | F05 | 45 | 46 | 6 | 126 | 87 | 13.5 | 105 | 178 | 11 | F05 | 45 | 46 | 7 | | 80 | 3" | 145 | 100 | 17.5 | 130 | 156 | 11 | F07 | 72 | 48 | 8 | 145 | 100 | 17.5 | 130 | 199 | 11 | F07 | 72 | 48 | 10 | | 100 | 4" | 170 | 124 | 17.5 | 157 | 218 | 14 | F07 | 91 | 54 | 10 | 170 | 124 | 17.5 | 157 | 243 | 14 | F07 | 91 | 54 | 12 | | 125 | 5" | 185 | 144 | 17.5 | 186 | 241 | 14 | F07 | 114 | 57 | 15 | 185 | 144 | 17.5 | 186 | 265 | 14 | F07 | 114 | 57 | 18 | | 150 | 6" | 203 | 150 | 18.5 | 216 | 264 | 17 | F10 | 145 | 57 | 20 | 203 | 150 | 18.5 | 216 | 312 | 17 | F10 | 145 | 57 | 25 | | 200 | 8" | 239 | 186 | 24.5 | 269 | 325 | 22 | F10 | 192 | 64 | 23 | 257 | 204 | 24.5 | 269 | 370 | 22 | F10 | 192 | 73 | 40 | | 250 | 10" | 275 | 226 | 24.5 | 324 | 394 | 22 | F10 | 240 | 71 | 42 | 288 | 238 | 30 | 324 | 438 | 27 | F12 | 240 | 83 | 65 | | 300 | 12" | 307 | 251 | 30 | 380 | 471 | 27 | F12 | 285 | 81 | 60 | 330 | 268 | 30 | 380 | 512 | 27 | F12 | 285 | 92 | 100 | | 350 | 14" | 337 | 294 | 30 | 416 | 520 | 27 | F12 | 328 | 92 | 100 | 337 | 294 | 39 | 416 | 579 | 36 | F14 | 320 | 117 | 200 | | 400 | 16" | 368 | 320 | 30 | 476 | 585 | 27 | F14 | 373 | 102 | 155 | 368 | 320 | 49 | 476 | 643 | 46 | F16 | 363 | 133 | 260 | | 450 | 18" | 406 | 341 | 39 | 534 | 625 | 36 | F16 | 422 | 114 | 200 | 406 | 341 | 49 | 534 | 705 | 46 | F16 | 400 | 149 | 380 | | 500 | 20" | 442 | 383 | 49 | 588 | 693 | 46 | F16 | 470 | 127 | 270 | 442 | 383 | 49 | 588 | 769 | 46 | F25 | 450 | 159 | 470 | | 600 | 24" | 493 | 442 | 49 | 692 | 807 | 46 | F25 | 570 | 154 | 420 | 500 | 442 | 58 | 692 | 908 | 55 | F25 | 550 | 181 | 780 |

|

Lug High Performance Butterfly Valves ★★★★★

Lug High Performance Butterfly Valves ★★★★★